Truck Shop

Senior Member

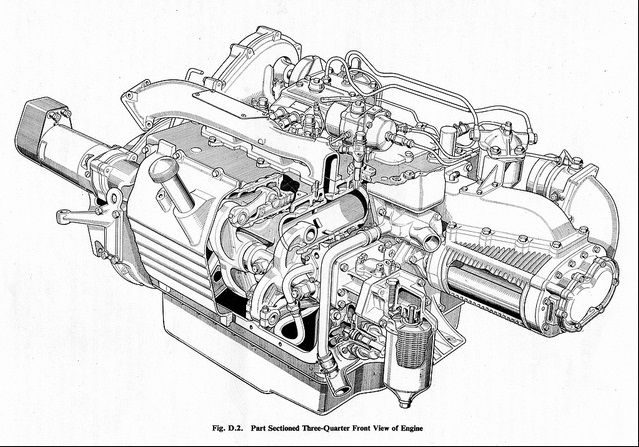

Well they better figure out how to make that potato masher make more HP and Torque or it won't sell worth Sh!t.----Fact. But the biggest problem with engines like that

are too many moving parts, always has been. First lesson for a design engineer-Keep it simple.

Truck Shop

are too many moving parts, always has been. First lesson for a design engineer-Keep it simple.

Truck Shop