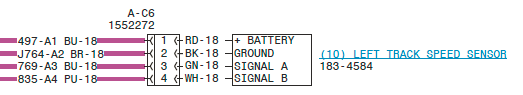

Update, Cat dealer did the coupler, $13k was the bill. So now 7888hrs machine has come to a stop again! Called CAT they can't make it till Fri. Just went out to look at it, first thing I noticed when trying to move it , it had no speed control, it was down on 1, tried to increase it , it would go up to 2 then drop back to 1. Got it turned around headed to where I wanted to move it to, started going, tried to speed up and it came to stop and gear ⚙️ light came on and parking brake light. Have to check codes. Anyone experience this?