Deas

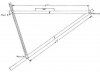

You are right about running just through the guide pullys. The boom we used was onsite anyway, and it is customized with the short boom for pulling a grid roller up and down the slope. It worked out well for the task. Had a really experienced hand at it too! 2nd day was interesting, as I had him lower me over the 1:1 at the top of the 5ft tall berm you see, went over it at a 45* angle, with nothing but already cut slope for the first 70 ft or so.

I hooked the choker around the lower ROPS mount, and it was very close to the center of balance, and allowed me to steer either direction, as needed.

I have also done this with a 14G blade, not in as extreme conditions as this, and tied the cable to the ear that holds the lift cylinder. we used a D-8K to pull with, hooked to the pusharm near the trunnion ball. We have also done this pulling ditches, and you would be amazed at how quickly you can finish.

Cascade

As Deas said, the slope board works better on top. if it is on the bottom, it only makes you slide more. It can keep you from overturning, but that is not generally the problem, as you slide way before you tip over.

I did take a slide off of a rock covered by only a few inches of dirt, so you couldn't see it till it was too late. When my tracks left the rock, the D-8K tipped up, and because the slope board was on the downhill side, I caught myself with it. Closest I ever came to tipping one over. Uphill track was 6 to 8 ft off of the ground. I was sidehilling because we werent allowed to dig in a road to cross this piece of ground.

When my tracks left the rock, the D-8K tipped up, and because the slope board was on the downhill side, I caught myself with it. Closest I ever came to tipping one over. Uphill track was 6 to 8 ft off of the ground. I was sidehilling because we werent allowed to dig in a road to cross this piece of ground.

You are right about running just through the guide pullys. The boom we used was onsite anyway, and it is customized with the short boom for pulling a grid roller up and down the slope. It worked out well for the task. Had a really experienced hand at it too! 2nd day was interesting, as I had him lower me over the 1:1 at the top of the 5ft tall berm you see, went over it at a 45* angle, with nothing but already cut slope for the first 70 ft or so.

I hooked the choker around the lower ROPS mount, and it was very close to the center of balance, and allowed me to steer either direction, as needed.

I have also done this with a 14G blade, not in as extreme conditions as this, and tied the cable to the ear that holds the lift cylinder. we used a D-8K to pull with, hooked to the pusharm near the trunnion ball. We have also done this pulling ditches, and you would be amazed at how quickly you can finish.

Cascade

As Deas said, the slope board works better on top. if it is on the bottom, it only makes you slide more. It can keep you from overturning, but that is not generally the problem, as you slide way before you tip over.

I did take a slide off of a rock covered by only a few inches of dirt, so you couldn't see it till it was too late.