Bobcat Crazy

Senior Member

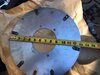

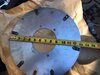

Well I received two more parts today. A replacement connecting rod for replacing the one on the journal where the crank broke. It was only a couple thousands out but I was afraid to reuse it. But @ $342 I'm glad I only needed one. And a flexplate at $225.

The good: the connecting rod was the correct part and is already installed on the piston and ready to roll when I get to that point.

The bad: The flexplate is the wrong one and has to be returned for the correct one

. See pics below for the difference.

. See pics below for the difference.

The good: the connecting rod was the correct part and is already installed on the piston and ready to roll when I get to that point.

The bad: The flexplate is the wrong one and has to be returned for the correct one

. See pics below for the difference.

. See pics below for the difference.