-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some Line Boring Pics

- Thread starter RayF

- Start date

Boring welder

New Member

What size bores on that bucket Ray havent done a 500.How long did it take?

Did you tow it on that trailer? Ian

Did you tow it on that trailer? Ian

RayF

Senior Member

Bores are 120mm. I normally knock one of those over in 8 or 9 hours. Very easy straight forward job. I did bring it home on the trailer Theres also a PC2000 bucket waiting to be bored at the same shop. I told them to put that on too

Theres also a PC2000 bucket waiting to be bored at the same shop. I told them to put that on too

RayF

Senior Member

994 Centre Pivot

I did the centre pivot this week. I put two machines on it and knocked it over in 21/2 days. Pretty straight forward job except I'm getting to old to be climbing up and down scaffolding all day

We used a piano wire to centre the bearings and all the way through then machined the top and the bottom seperately but still within 1 or 2 thou of alignment.

I did the centre pivot this week. I put two machines on it and knocked it over in 21/2 days. Pretty straight forward job except I'm getting to old to be climbing up and down scaffolding all day

We used a piano wire to centre the bearings and all the way through then machined the top and the bottom seperately but still within 1 or 2 thou of alignment.

RayF

Senior Member

The piano wire gauge is a great tool for getting alignments right. The wire is insulated from earth and carries a 1.5 volt current.A pair of headphones are connected and when a mike shorts out the wire you get a crackle in the phones. The difference between a crackle and none is half a thou.We centre the wire in the top and bottom bores first and then line the intermediate bearings to the wire.

Attachments

TOM V

Senior Member

Nice job as usual Ray.

steve loving

Well-Known Member

Ray Nice job that climbing get harder every year. Im surprised the loader frame isnt wider than it is. I have never been around a 994 but its a big one Steve

RayF

Senior Member

Those 994's are quite narrow. I remember when they first came out the tyres where a lot narrower and there was one up at Argyle diamond mine that used to fall over a bit It was also known as the "Moth" Everytime the workshop light came on it drove in

It was also known as the "Moth" Everytime the workshop light came on it drove in

And I am getting to old to be climbing up on those things. These days I would be happy to leave that work to younger men and I can stay in my shed and do a bit of lathe and mill work

And I am getting to old to be climbing up on those things. These days I would be happy to leave that work to younger men and I can stay in my shed and do a bit of lathe and mill work

OldandWorn

Senior Member

And I am getting to old to be climbing up on those things. These days I would be happy to leave that work to younger men and I can stay in my shed and do a bit of lathe and mill work

Hey! you could start a new industry....Mobility Scooter Lifts for the elderly mechanic :tong

Ray, where do you get a reference point for the piano wire?

Is the white stuff on the welds for crack inspection?

RayF

Senior Member

Mate,easier to just stop doing it Maybe not

Maybe not I threaten it all the time but they con me into one more job.

I threaten it all the time but they con me into one more job.

Yes the white paint is where they have mag particle tested for cracks. They spent a few weeks on welding on this machine.

In this case we centered the wire to the top and bottom bores. You can centre to any bore that you know is in the original position although with an artic pivot a few thou out of position is not the end of the world. Its just important that everything is in line.

Yes the white paint is where they have mag particle tested for cracks. They spent a few weeks on welding on this machine.

In this case we centered the wire to the top and bottom bores. You can centre to any bore that you know is in the original position although with an artic pivot a few thou out of position is not the end of the world. Its just important that everything is in line.

RayF

Senior Member

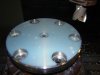

At last I have a break from onsite work and have had a chance to get into some lathe and mill work One of my clients is building a new Hitachi EX1900 bucket and I'm currently doing the bosses and caps for the floating pins.I've been working on the caps the last few days.They are cut out of 50 mm plate by 270 diameter.18mm holes on a 220 PCD and a 42 mm counterbore. I had a slot drill which did the job nicely. I was a bit concerned it would be too big a cut but it cut easily

One of my clients is building a new Hitachi EX1900 bucket and I'm currently doing the bosses and caps for the floating pins.I've been working on the caps the last few days.They are cut out of 50 mm plate by 270 diameter.18mm holes on a 220 PCD and a 42 mm counterbore. I had a slot drill which did the job nicely. I was a bit concerned it would be too big a cut but it cut easily

Last edited:

RayF

Senior Member

OldandWorn

Senior Member

Do you find it easier to use the rotary table rather than the bolt hole circle routine on the DRO. I assume your DRO has that feature?

RayF

Senior Member

Yes the readout does do bolt circles. I just found it easy to use centre as a datum,shift the table along the radius and start drilling.I put a paint pen mark at 60 deg intervals on the rotating table scale so its quick and easy shift. I'm open to suggestions. In no way am I an expert miller. I just feel my way

I'm open to suggestions. In no way am I an expert miller. I just feel my way

OldandWorn

Senior Member

Makes sense to me with multiple pieces now that I think about it. That would be a lot of wheel spinning using the DRO.

TractorSteve

Member

Looks like you found yourself a pretty neat nitch market. It looks like you have the know how to do a great job, and then do it. I for one would enjoy seeing more of your work, when you have time to share it with us. Someday I would like to see all the steps and how it is done in person. Always like to know more about mechanical things.

Agreed. You've done a great job I'd definitely like to see more of your work and the step-by-step process.

steve loving

Well-Known Member

Looks good Ray what hp is your new mill. Does it use cat 40/50 tooling?