TOM V

Senior Member

Jim correction onthat ram, it is 3.5" long with 1/2" stroke

That's pretty slick Willie.

That's pretty slick Willie.

Here's a cool 3/4" drive ratchet that we purchased for our service truck, the EZ Red MR34. It has a knurled handle for good grip, and is 24" long.I have a 1/2" one like that, snapped the head off it on a lugnut. KingTools is the brand. I had it for about 20 years, it was a sad day,

So I get out the trusty google engine, search, find, email, then get a phone call,

They say the usual whatevers, which translated to out of luck, put on hold, miracle happens, send tool to them at my cost for a new tool.

I'm now the proud owner of a brand spanking new ratchet, although it's not my favorite ratchet . but the always there cheater pipe is handy.

that would be one of the few snap on tools that I own ... a crooked 3/8" flex ratchet... the best thing about it is the kids don't like it.

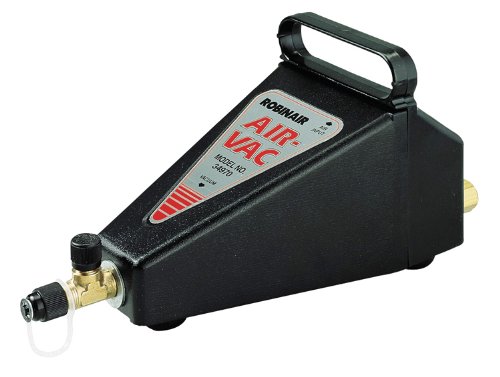

It is an air powered vac pump designed for servicing air conditioning systems. It works by blowing compressed air through a venturi. They are low volume, but they will pull a hard vaacum.

Ok all you wrench benders, this is a shop forum, let's see the tools and gagets you work with to get something done. There's a lot of small owner/operators/repaimen on this forum that I'm certain would like to see "a better way" to get a task accomplished. I think I've posted these pics somewhere buryed in the forum sections, beats me where the heck they are though, so I thought a designated tools thread would be a good reference place for the useful shop tools that we work with.

This is a tool that's as handy as a handle on a shovel head. A hollow ram Enerpace hyd cylinder. This one goes for around $850 to $1000 retail depending on where you look, I scored this one on ebay for $375 + shipping, no regrets spending that money for this tool. You can use it as a typical pushing jack cylinder like other porta power cylinders, but you can also insert up to a 1 1/4" rod through it to perform pulling tasks. It's handy for removing and install bushings in cylinder rod ends for example. Very handy shop tool, have used it on many occasions.

I've got it set up here to remove and install rubber isolater bushing inserts on a Case Maxi-Sneaker vibratory plow. Ever tried to remove or install compressed rubber inserts with a hammer? Good luck with that! With this tool, piece of cake. Here's the removing set up with a pushing sleeve on backside of the insert.

View attachment 71227

Tighten the nuts on the threaded rod until pushing sleeve is against the steel bushing in center or rubber insert,

View attachment 71228

Then simply pump the cylinder.

View attachment 71229

Bushing removed slicker than snot on a door knob.

View attachment 71230

Re-installed new bushings by greasing everything with silicone lube, fitted new bushing on backside of square tubing socket, fitted up the pulling rod and simply pulled the new isolater in place. I've used this tool to install bushings on loader arms, excavator bucket pin bushings, all kinds of tasks I used to do with a sledge. I'd rather use this tool as opposed to a sledge anyday.