cpmartin1989

Member

Morning all, I have Komatsu PC35R-8 Serial #F21286.

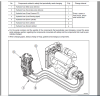

The machine has 1100 hours on it, had no issues when I purchased it approx 3 months ago. I does have one leaking cylinder but not critical to operation and not a significant loss. Recently I seam to lose power after the machine is on and hydro heats up. First indication was the left track seems to lose power, (tracks straight though) replaced final drive oil all looked to be good, no shavings. I borrowed a thermal imaging gun from work and it appears that the very bottom hose coming into the 9-spool control valve is getting warm quickly. Along with what I believe to be position 3 (pressure compensation valve R (boom swing - blade). Reading the operators manual it suggested cleaning the suction filter, I was a little hesitative as it said this was a 2000hr maintenance item. I did clean and refill with proper oil (like 300 bucks worth of fluid) did not fix the issue. It sounds like a small hiss coming from the 9 spool valve, I think maybe a valve may be stuck open/partially open/etc. I am not ready to rip into that valve body until I can come up with a really refined idea of what it could be. I will be more than happy to answer any questions anyone has.

The machine has 1100 hours on it, had no issues when I purchased it approx 3 months ago. I does have one leaking cylinder but not critical to operation and not a significant loss. Recently I seam to lose power after the machine is on and hydro heats up. First indication was the left track seems to lose power, (tracks straight though) replaced final drive oil all looked to be good, no shavings. I borrowed a thermal imaging gun from work and it appears that the very bottom hose coming into the 9-spool control valve is getting warm quickly. Along with what I believe to be position 3 (pressure compensation valve R (boom swing - blade). Reading the operators manual it suggested cleaning the suction filter, I was a little hesitative as it said this was a 2000hr maintenance item. I did clean and refill with proper oil (like 300 bucks worth of fluid) did not fix the issue. It sounds like a small hiss coming from the 9 spool valve, I think maybe a valve may be stuck open/partially open/etc. I am not ready to rip into that valve body until I can come up with a really refined idea of what it could be. I will be more than happy to answer any questions anyone has.