So my “fairy tale”:

The yellow is “we are leaking some pressure but we don’t really care about it because flow demand and pressure is low” zone!

The green is: “we are doing OK with medium flow demand” zone

And the red is: “Oh! Crap! We are in high flow demand and leaking pressure off”zone.

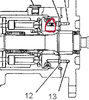

All this time I wondered: why there’s channel from pumps discharge to front cover?!

The problem is I haven’t paying attention to the pictures ( and I haven’t seen all the pictures of this thing)! The swash plate bearing lubrication doesn’t come from the swash plate face, it comes through the channel in the front cover, through slot in one of the swash plate journals, through channel inside the swash plate body and to the journal on the other side!

This is either design flaw or assemblers error, the swash plate bushing that on the side where journal do not have slot in it - should not have the lubrication hole in it ( or should e flipped 180*, to the side where the swash plate do not move to in open loop pumps)!

I think delamination started from the sharp edge in that hole where oil under high pressure started getting in between the coatings layers!