TorchHypnosis

Active Member

Where is the map sensor?

Can you post the last eight of the VIN. It does sound like a fuel issue, 58 psi is on the low side but going down the road it may be lower under load.

(note - when I unscrewed the fuel pressure regulator 3-5 Tbsp of what looked like black motor oil trickled out, thought that was odd)??

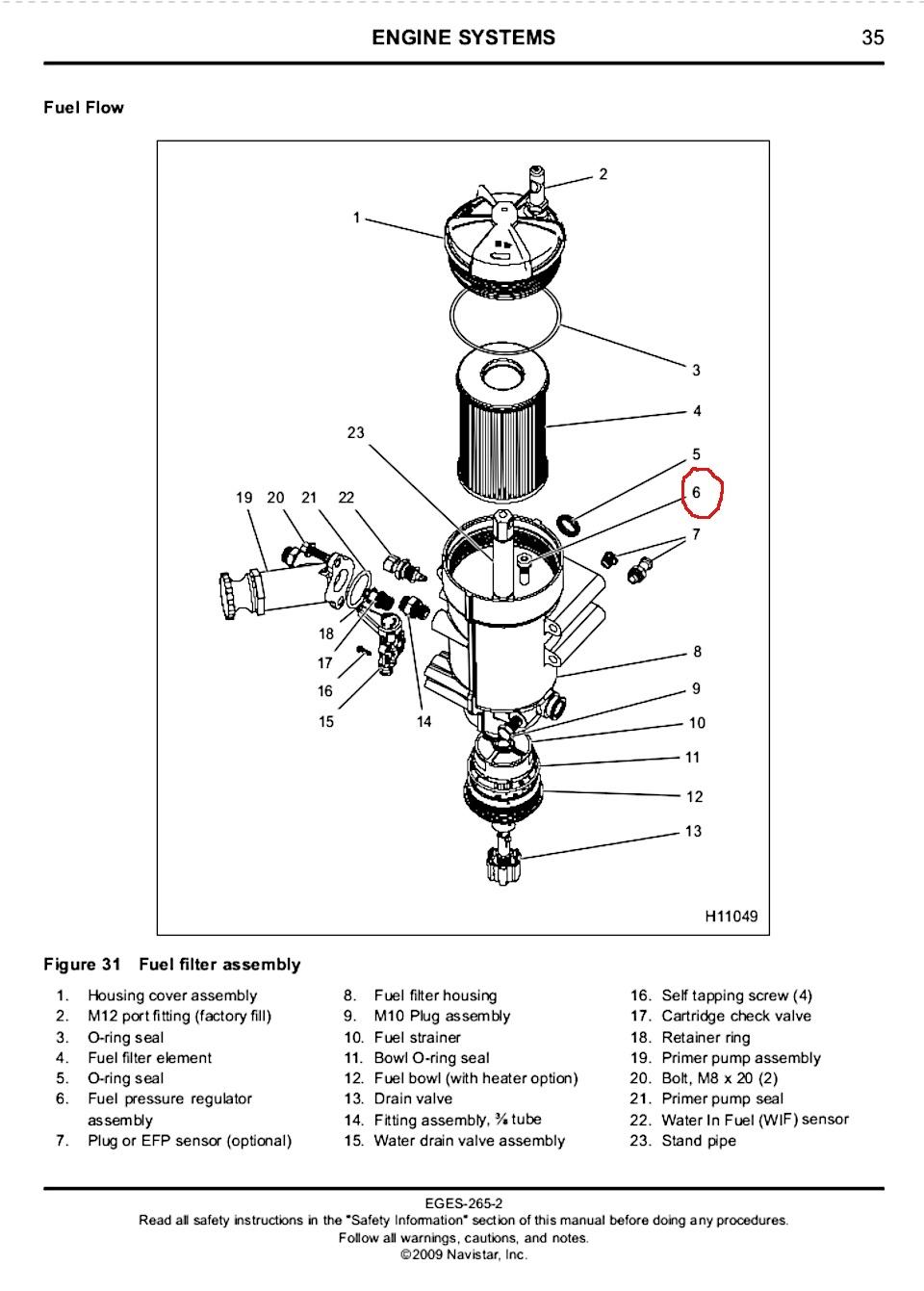

What is the fuel pressure regulator you are referring to here?

When you changed the filter was there a buildup of dirt and debris in the bottom of the housing?

The fuel pressure regulator is located in the bottom of the filter housing. Its a stainless orifice with a small spring loaded plunger in it. Take it out and blow it out with compressed air. You will need a 7mm allen socket to remove it.

The 07 DT466 does not have a fuel return line. The fuel from the regulator returns back to the fuel inlet on the filter housing. If there is crud in the filter housing it goes through the regulator in the bottom of the housing back into the inlet through the transfer pump and back into the filter housing. It keeps going around and around until it builds up on the seat of the regulator dropping the fuel pressure.

The tube in the middle of the fuel filter housing has holes in it where the filtered fuel goes into the engine. Don't let anything get in there when cleaning the housing.

If there is a lot of crud built up in the bottom of the filter housing with the fuel pressure regulator removed take the fuel supply line off the filter housing and clean and flush the housing, the debris will drain out of the filter inlet. You can remove the housing to clean it you will need the oval O-ring that seals the housing to the intake manifold.

There is a strainer on the bottom of the housing that can get plugged over time. Its probably never been cleaned.

An 07 should have a quick coupler on the plastic filter cap. Plumb a gauge in there and see what the pressure is under load.

The faults with the turbo actuator should not cause the power loss you have but a boost leak would.

Aah...thanks for that cfherrman.The Ford 6.0 diesel engine, a heui engine made by international, vt365.