-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CAT 299D won't move

- Thread starter Jeffrey Bandel

- Start date

Jeffrey Bandel

Senior Member

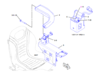

My CAT tech came today to program the new monitor. Took about 5 minutes. We talked about why it locks up when backing up. It is throwing a right hand speed sensor code again. As a refresher, this fall he and I independently verified the wiring back to the ECM was good and I installed a new sensor. He said he has seen this situation a few times. He thinks the wiring tests good when cold, but when it heats up it can cause problems (this makes sense because it doesn't lock up until I use it for about 15 minutes). So I am going to start looking at the harness from the pigtail close to sensor to the junction under the cab behind the seat.

Jeffrey Bandel

Senior Member

I didn't look. I was in a hurry to get on the road for Christmas travels. I'll post later this week.

Nige

Senior Member

if you look way back in the thread (1st couple of pages?) Chris, the Code it was throwing was posted.When the speed sensor sets a code, what is the FMI? (Failure Mode Indicator. The last two digits)

Nige

Senior Member

CID2685 FMI02.....!!

Nige

Senior Member

If you trawl through the thread I think there was something somewhere regarding doubts about the lap bar switch. That would stop it in a heartbeat.

Jeffrey Bandel

Senior Member

Nige. I'll go back through the thread because I don't remember the lap bar switch--I thought it was the seat switch and upgrade.

Nige

Senior Member

Jeffrey Bandel

Senior Member

Jeffrey Bandel

Senior Member

I believe I fixed the problem. I have about 20 hours of use without it throwing a code or stopping. I replaced two sets of wire harnesses from the right side speed sensor. The old wires and the new wires tested good. I guess when the old wires warmed up, they failed.

Nige

Senior Member

If you have indeed fixed it you've conquered the Everest of electrical faults, the intermittent one that comes and goes with temperature, vibration, etc, etc. Fingers crossed for you.

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,165

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

Reading about this problem just reminded me of a machine I worked on many years ago. Not anywhere as complicated but still had an electrical problem that would come and go. Believe it was a Hough 560, company had many of them around the area back then.

Believe it finally started acting up when machine was articulated from one side to the other. Long story short is one of the wires running through a section of rubber hose at the center of the machine had a fault in it. What was strange is the way the wire was broke but the insulation did not look damaged on the outside. Almost like someone butted the wire strands together as it was going through the machine to have insulation molded on it! Machine was not that old to where the bit of flexing from the steering of the loader could have fatigued the wires and it was only one out of a dozen or more in the harness that had a problem.

Got my fingers crossed that your problem is gone for good!

Believe it finally started acting up when machine was articulated from one side to the other. Long story short is one of the wires running through a section of rubber hose at the center of the machine had a fault in it. What was strange is the way the wire was broke but the insulation did not look damaged on the outside. Almost like someone butted the wire strands together as it was going through the machine to have insulation molded on it! Machine was not that old to where the bit of flexing from the steering of the loader could have fatigued the wires and it was only one out of a dozen or more in the harness that had a problem.

Got my fingers crossed that your problem is gone for good!

Mobiltech

Senior Member

Speaking of skid steer weird electrical faults I had a 297c that would have 12 volt power everywhere when you turned the key on but when you went to start everything went out and lost all voltage. I lifted the cab and checked battery which load test good with cables installed. Hard to get to starter but I managed to load test at starter and found voltage dropped to 0 under load. The battery is under the cab and the cables are only 2 feet long. I tested ground to frame and it was good. Positive cable looked like new but was losing 12 volts in 2 feet. Cleaned battery connection with no luck. Pulled off positive cable and cut the factory moulded battery clamp end apart and found it was green where the cable and the clamp were moulded together.

Nige

Senior Member

Believe it or not I had a similar experience on a battery-operated clock not that long ago. Someone had left old dry cell batteries in it and the corrosion from them had travelled down both the positive & negative wires right to the soldered connections of the circuit board. Outside they looked fine, inside they were pretty much like dust. 10 mins with the soldering iron later, happy daze.......