Oh trust me, Im not mocking you in the least! Its just Ive seen this scenario many times and more times than not, it becomes a basket case. There is a lot of special tools, torque specs, clocking precups and such, it can get more expensive than you anticipate in a hurry. I and the others will help you as much as we can, but you also have to realize your limits. I admire the fact that you are hands on for sure, not many would even attempt to tackle such a project with little to no service specs and tooling.I have the "pre cup" spacers because they are rusted to the pre cups. I don't understand why you think I am way over my head. I own a construction company but I have always did my own mechanic work, that includes my diesel and gas trucks. This caterpillar engine is unchartered territory for me hence the reason I joined this forum and was seeking help from the great people here who know this engine or have experienced the same problems I am having. Over my head? It really doesn't seem hard to buy a special little tool to put the precombustion chambers back in so that the glow plugs are In the right spot and if not to change the spacer on the bottom with a different one that's in my kit. I really appreciate all the awesome help that I have received this far. Btw I did number each pre cup when I pulled it but that's really erelvant because I think I'm just gonna buy all New ones since they're only about 100 bucks and the tips are only about 100 bucks so I feel it will be safer with New equipment instead of using this abused stuff.

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CAT 955K TURNS over but wont run.

- Thread starter Themaskman72

- Start date

and if you put 4 gallons of coolant in the radiator before starting this project, it had to go somewhere. The system was either not completely full, or the coolant is somewhere it shouldn't be. I agree with Ken, crack the drain plug or valve at the oil drain, and see if you have antifreeze there, or somewhere on the ground. It may be in the belly pan also.

Themaskman72

Well-Known Member

Too be honest I have enjoyed working on this machine, I find it easier than working on my trucks. Everything is easy to get to and simple with no computer stuff. I love learning New stuff and you guys have been great teachers. There isn't any coolant on the belly pan, I'm guessing it wasn't full to begin with. I will have a better idea when I get the pre cups back in and the nozzles.

oarwhat

Senior Member

I also want to say I wasn't mocking you. I'll ask the same question as Kshansen how bad were the o`rings around the top of the chambers? I had a 3306 that kept cooking those orings. It ran somewhat warm but no overheat. Turns out my oil cooler was plugged. Make sure you clean the head where they seat also.

Themaskman72

Well-Known Member

I cleaned the head really good and believe me it needed it, when I pulled the pc's and nozzles I have yet to find any seals anywhere on either or on the head.

The spacer for the precup is the seal for the threaded end, which is why that location needs to be super clean. The upper seal is a oring that goes into the grove on the large end of the precup. If there wasn't any orings there when you pulled them out, that may be why there was no coolant in the head.

oarwhat

Senior Member

There's supposed to be an oring in the groove in the pre cups. Just below the number you put on them. Without the oring antifreeze will pour right out. I see in the pictures just remnants of an oring in there.

I have to tell you by looking at those pictures when the owner told you " it ran great when he parked it. After it Sat for a year he went to move it and it would turn over but not start. So it Sat another year and Now I have it. " He's lying through his teeth. No way a good running machine, with a rebuilt head would look like that after sitting for just 2 years. No way ho how!!! but that's a moot point now. You need to find out why the anti freeze isn't getting to the head and where it went.

Looking at what's left of those orings I bet they cooked it again and parked it. Again good luck and keep us informed

I have to tell you by looking at those pictures when the owner told you " it ran great when he parked it. After it Sat for a year he went to move it and it would turn over but not start. So it Sat another year and Now I have it. " He's lying through his teeth. No way a good running machine, with a rebuilt head would look like that after sitting for just 2 years. No way ho how!!! but that's a moot point now. You need to find out why the anti freeze isn't getting to the head and where it went.

Looking at what's left of those orings I bet they cooked it again and parked it. Again good luck and keep us informed

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,165

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

The spacer for the precup is the seal for the threaded end, which is why that location needs to be super clean. The upper seal is a oring that goes into the grove on the large end of the precup. If there wasn't any orings there when you pulled them out, that may be why there was no coolant in the head.

Yes that washer/spacer/gasket at the bottom is what seals the combustion gases in the cylinder and keeps the coolant out of the cylinder. That is why everything down that end has to be very clean and a new one installed every time. Still even if the oring was gone from the top groove of the chamber the coolant should have still been below that point in the head or at least some should have been in there!

That is why I wonder about where the coolant went. Those top seals/orings can deteriorate to the point of being almost completely gone from over heating.

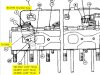

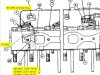

Just so we are all understanding where this orings are look at the picture below, they would be where the red arrows are pointing.

Definitely agree. That is a lot of coolant to just disappear from sitting for so long. I wonder if maybe a coolant hose somewhere may have dry rotted and leaked the coolant out over time. Water pump seal?:beatsmeYes that washer/spacer/gasket at the bottom is what seals the combustion gases in the cylinder and keeps the coolant out of the cylinder. That is why everything down that end has to be very clean and a new one installed every time. Still even if the oring was gone from the top groove of the chamber the coolant should have still been below that point in the head or at least some should have been in there!

That is why I wonder about where the coolant went. Those top seals/orings can deteriorate to the point of being almost completely gone from over heating.

Just so we are all understanding where this orings are look at the picture below, they would be where the red arrows are pointing.

View attachment 163595

Themaskman72

Well-Known Member

Hypothetically speaking....let's say there is a blown head gasket or even worse a cracked head, wouldn't the machine still run, I mean it was parked where it is, it didn't just die there. How do you go about running a compression test to check it?

Nige

Senior Member

Believe it or not but the best way to test for cracks is to pressurize the cooling system by filling it up with water and then putting 10-15psi of pressure into the radiator and observe whether the pressure stays there or not. If it doesn't then you go hunting for leaks.Hypothetically speaking....let's say there is a blown head gasket or even worse a cracked head, wouldn't the machine still run, I mean it was parked where it is, it didn't just die there. How do you go about running a compression test to check it?

As others have posted I would be looking at obvious places like hoses that could have deteriorated while the machine has been sitting parked, the water pump seal, etc, etc.

The fact that there was little trace of o-rings in the large groove at the top of the PC chambers is quite frankly worrying. With no sealing at that point any coolant you added to the radiator should have simply pi$$ed all over the floor - there's nothing to keep it in .... The $64,000 question is WHY the o-rings were so rotted. Again as others have pointed out if that particular engine model is overheated one of the first things that usually let go is those o-rings. Simply as a "what if" because you were not there when the machine was "parked", did it look to you as though it had been parked in a specific location or simply abandoned wherever the person who last used it hopped off...? That might give us some clues. Also how long was it parked as a non-runner..? That also might give a clue as to why rubber parts are so deteriorated. There may be more to this engine than the previous owners/users are telling you ....

Last edited:

Themaskman72

Well-Known Member

Yes it is setting beside a shed as if it were backed in and parked there. After I properly seal the pc's I'm gonna run the coolant system test and go from there. I think it would be better to run the test before I try to fire it again in case it fires and allows coolant to go somewhere it shouldn't.

Nige

Senior Member

Don't use too much pressure. 10-15psi should be fine. What you do need is an accurate pressure gauge that reads up to say 30-50psi and a leak-free shut-off valve so that when you get the pressure in the system you can close the valve and watch the gauge carefully to see if it holds pressure.Yes it is setting beside a shed as if it were backed in and parked there. After I properly seal the pc's I'm gonna run the coolant system test and go from there. I think it would be better to run the test before I try to fire it again in case it fires and allows coolant to go somewhere it shouldn't.

Dased on your comments about where it's parked we could be reading too much into this - the rubber deterioration could simply be due to age. However having got to this point I think it's better to proceed one small step at a time instead of 3 steps forward, 2 steps back. A pressure-tight cooling system is a must before moving on to try and start it again, which is I guess where we came in .....

thepumpguysc

Senior Member

- Joined

- Mar 18, 2010

- Messages

- 7,539

- Location

- Sunny South Carolina

- Occupation

- Master Inj.Pump rebuilder

If you don't have 1, Harbor freight, Northern tools sells a cheap cooling system checker w/ multiple caps to pressurize the system.

Nige

Senior Member

While I remember (and at the same time as you're working on pressure testing the cooling system) don't forget to try ksh's suggestion of opening the engine oil pan drain and see if you get any water and/or coolant out of it ..... that could give important clues as to the health of the engine. A few drops of water then oil is probably no more than condensation, the presence of glycol or large quantities of water potentially means something more serious.

Themaskman72

Well-Known Member

Thanks it will probably be the weekend before I can get back on it, working the rest of the week, I will update you as soon as I do the test.

Themaskman72

Well-Known Member

I need some assistance, the seals that the guy at CAT ordered for me are not right. Can someone tell me the part number for the spacers on the bottom of the pc's and also the part # for the rubber o ring that goes around the top to seal the coolant in, thank you.

Nige

Senior Member

Did you order parts based on the machine Serial Number or the engine Serial Number..?

Your machine was one of the first where the engine carries a separate Serial Number, up to 85J6000-odd the engine was a D300-series and carried the same Serial Number as the machine.

I'd suggest you post your engine Serial Number to help us help you.

Also give the Part Numbers of the 2 items that came wrong, so someone can track down what they are supposed to fit.......

Your machine was one of the first where the engine carries a separate Serial Number, up to 85J6000-odd the engine was a D300-series and carried the same Serial Number as the machine.

I'd suggest you post your engine Serial Number to help us help you.

Also give the Part Numbers of the 2 items that came wrong, so someone can track down what they are supposed to fit.......

kshansen

Senior Member

- Joined

- Mar 11, 2012

- Messages

- 11,165

- Location

- Central New York, USA

- Occupation

- Retired Mechanic in Stone Quarry

Did you order parts based on the machine Serial Number or the engine Serial Number..?

Your machine was one of the first where the engine carries a separate Serial Number, up to 85J6000-odd the engine was a D300-series and carried the same Serial Number as the machine.

I'd suggest you post your engine Serial Number to help us help you.

Also give the Part Numbers of the 2 items that came wrong, so someone can track down what they are supposed to fit.......

I agree I looked in SIS and see where they want to know the S/N of the engine. I could give the numbers I saw there but would like to be sure they are the right ones. Also would like to know why your dealer can not come up with the right parts as he should have as good and hopefully much better access to parts information than some retired guy sitting at home on his computer, that would be me!

Maybe even be worth the effort to take a picture of these "wrong" parts, I'm very curious as to what they did send you. These Pre-chamber gaskets and seals should not be that hard to look up. Of course it is possible they "parts guy" was not even born when these were common parts. I could almost guarantee I could run up the road to the quarry where I worked and pick a set of them right out of the cabinet where I kept an assortment of them in stock at all times.

Last edited: