chansey

Well-Known Member

Finally had some time to work on the loader today.

The spacer that was made to make up the gap between the flywheel and torque converter drive plates fit perfectly.

Made the front motor mounts today. Used some spring perches from a heavy truck that were L-shaped for the lower plate. The engine came with "shop fab" mounts attached to the engine. Made them work with the pieces I made up. Used mid-90's Dodge 2-piece cab mounts for the motor mounts. Works great as the lower half goes into the lower plate and protrudes about 3/8" above the plates. The upper half has a molded-in steel [late and a recess where the protrusion nests into. I have used these on other installations and the work exceptionally well.

The Trojan OEM transmission oil cooler would not fit in the position where it was installed for the Deutz. Even if it would have fit, I would have had to add a cooling fan because the Deutz had a sheet metal air duct supplying air. Stopped by a heavy truck parts salvage yard and picked up a oil cooler from a C-15 Cat engine. I just need to run water to the cooler. The tube bundle has large castings on both ends that mount to the engine. I have removed these and will be modifying the tube bundle by machining bell ends with bolt tabs to tie the bell ends together to keep them from leaking.

I'll attach photos of them fab parts later.

Tomorrow the radiator and air cooler go in and then all I have is electrical and we'll fire it up.

Paul

The spacer that was made to make up the gap between the flywheel and torque converter drive plates fit perfectly.

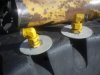

Made the front motor mounts today. Used some spring perches from a heavy truck that were L-shaped for the lower plate. The engine came with "shop fab" mounts attached to the engine. Made them work with the pieces I made up. Used mid-90's Dodge 2-piece cab mounts for the motor mounts. Works great as the lower half goes into the lower plate and protrudes about 3/8" above the plates. The upper half has a molded-in steel [late and a recess where the protrusion nests into. I have used these on other installations and the work exceptionally well.

The Trojan OEM transmission oil cooler would not fit in the position where it was installed for the Deutz. Even if it would have fit, I would have had to add a cooling fan because the Deutz had a sheet metal air duct supplying air. Stopped by a heavy truck parts salvage yard and picked up a oil cooler from a C-15 Cat engine. I just need to run water to the cooler. The tube bundle has large castings on both ends that mount to the engine. I have removed these and will be modifying the tube bundle by machining bell ends with bolt tabs to tie the bell ends together to keep them from leaking.

I'll attach photos of them fab parts later.

Tomorrow the radiator and air cooler go in and then all I have is electrical and we'll fire it up.

Paul