Doug, you may very well just need to do a little adjustment on the right clutch, or maybe the linkage. We have posted lots of stuff about steering clutches and brakes in the last 10 pages or so. You might want to read some of the posts from them to give you an idea of how the steering works. But I'll throw in a few comments first with my thoughts on what it may be.

I'm assuming the left track will stop completely when you pull back on the left brake handle, so it appears to be working fine. The normal mode for the steering clutch and brake, when the steering handle is not pulled out, is that the clutch is fully engaged and the brake is disengaged. When you pull back on the handle slowly, with proper adjustment, the clutch will disengage first, allowing that track to be free-wheeling. As you pull back further, the brake will engage, stopping the track from turning altogether. On my D20A-6, if I pull back slightly on the right steering handle, it will start a slow turn to the right. If I pull back further, it will pivot sharply on the right track.

I'm thinking your right clutch is not engaged completely, therefore the left track is pushing harder and causing it to want to go right all the time. There is an adjustment screw that determines how much the clutch release is pushed. I suppose it could be adjusted such that the clutch is always partially released. And you could just have worn clutch plates, but I would think that the ones on the left would be close to the same shape if that were true. And the linkage from the steering handle to the actuator that is pushed in on the steering valve assembly could possibly be always pushing the actuator in a little, causing it to send hydraulic fluid to the piston that pushes on the clutch release, but that's not a common problem, from all I've read.

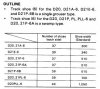

Pulling the clutches is not an easy job. There are posts on this forum that others have written detailing their experiences with that, and it doesn't look like a lot of fun to me. I would try everything else before I went that route, if I were you. It's not that hard to remove the seat and the floor plates, and then you can see the linkage moving and you'll see the actuators on the steering control valve assembly that the handles push in. If you have the shop manual, it will help a bit, but the pictures in it are terrible, and it's very hard to see details of any kind. You might want to look at the Komatsu Parts Book website and find the parts breakdown so you can see more details. I know I've posted links to it a couple of times in the last few pages here.

Good luck with it, and please come back and tell us what you find. It helps us all to learn more, and you may save the next visitor a lot of time and frustration.