Thanks very much!

Well, a few weeks ago I had an E15 and discovered fuel wasn't exiting the tank well. Removed the clog and it worked.

A week ago, oil started spitting out of the overflow. Thought maybe it was too cold and wouldn't circulate so Left it with a heater overnight. Still no good.

Changed the oil & filter. Oil was very thin. Still no good.

Also noticed fuel coming out from the lift pump area.

Oil smelled like diesel and was way too much of it.

Replaced all the injectors, which looked quite burned.

JB Weld on the spot where the lift pump dripped.

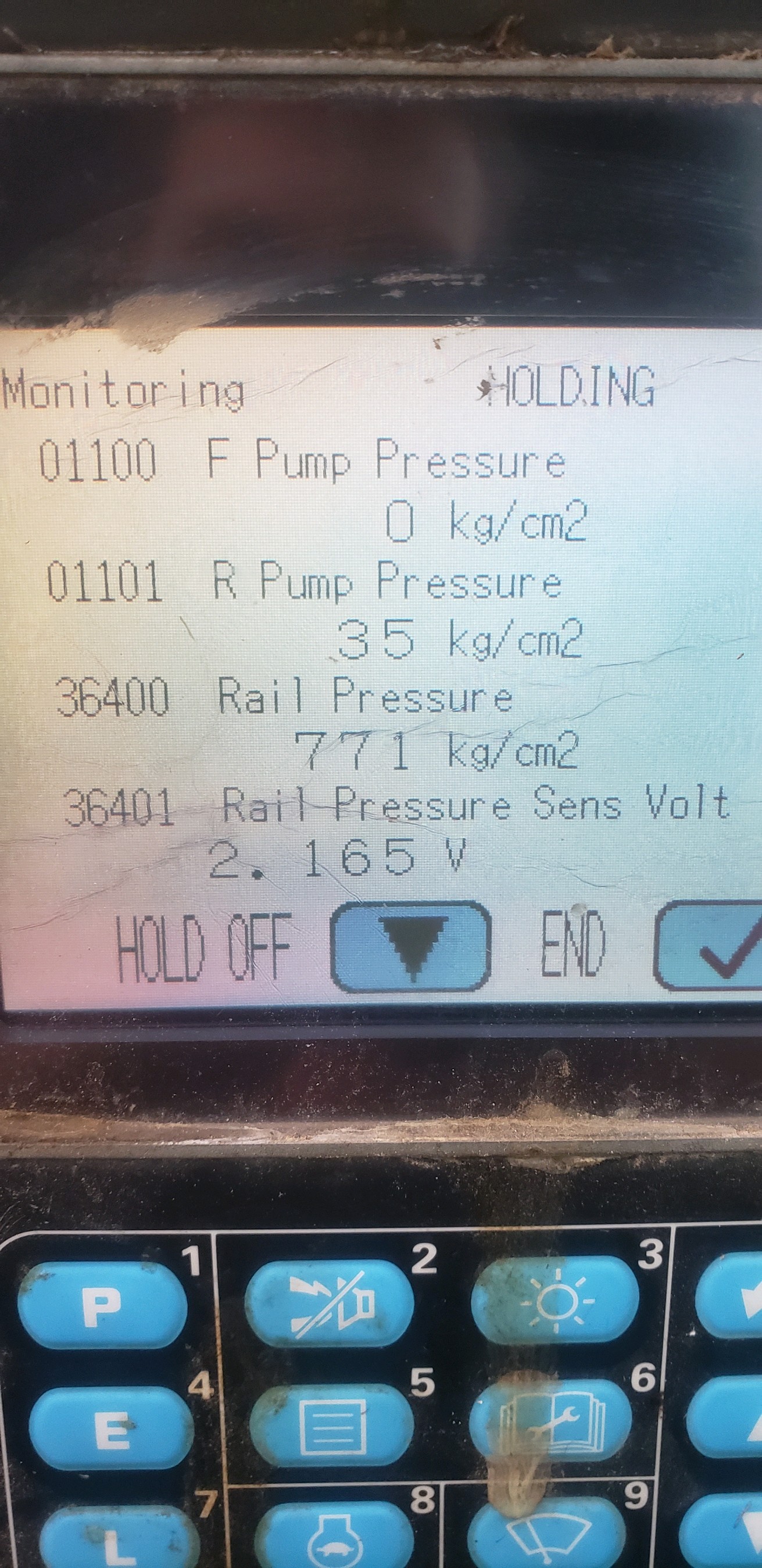

Put it all back together and it runs like crap, threw a CA553 and now an E15 code.

When waiting for the injectors to come, rain might have gotten into the engine (yep, left the valve cover off).

Changed oil and filter, and fuel filter. Lots of water in both.

Took rail off and I think port 3 is clogged. Thinking it might be ice, so I brought it inside overnight.

Took pressure sensor off and cleaned.

Cleaned out the return lines (CA553 is abnormally high pressure).

Cleaned the cylinder pressure relief valve (bolt).

Will clean everything again this morning, reinstall and see where we stand -- and report back.

Thank you!