The machine started having an issue (once in awhile and now more often) when going to reverse. The machine has to be shut down and restarted to get it to go. Tonight it feels like it’s trying to catch and then letting go. I did notice if you let it idle in gear sometimes it will catch. The Volvo also had a problem close to the same. I pulled some codes tonight as follows: E0049.3, E0155.0, 0673.02, 0585.02 and 0562.09. Don't have a clue what they are but we'll call Cat in the morning.

IMHO the 88 doesn’t have the wheel power the 350 did when pushing loads but I'd still rather have the 88. When the machine is pushing real hard in 1st you can hear and feel the power being reduced (by the computer I'm guessing) (maybe to reduce wheel slip?). The 88 is a little harder for an old fart like me to get in because the arm rest/steering controls don't move very far. The cab is quiet enough and comfortable. The mirror on the left side should have been mounted in another place because it the door is opened too far it hits the mirror you'll have to get back out and readjust it. < is about the only complaint other than the shifting problem which I'm 100% sure Cat will cure.

Simple things first, and I know this post is from a while back. There should be a rubber stop assembly to prevent the door hitting the mirror. Maybe it got left out when the reapir work was done to the cab roof after the loader hit the bridge while being transported to the job site..?

Fault Codes

562.09 - Cat Monitor System

585.02 - Transmission Output Speed Sensor #1 (there are 2 sensors)

673.02 - Transmission Output speed Sensor #2 (well golleeeee, do we see a pattern here?)

02 - data erratic, intermittent, or incorrect

09 - control not receiving expected information (I would guess from the transmission speed sensors in this case)

I would suspect a harness connector fault, maybe something as simple as a plug not fully home in a socket.

Event Code E049 is a Coasting in Neutral Warning - naughty, naughty.

Event Code E155 is a High torque converter outlet oil temperature - again naughty, naughty.

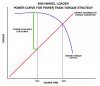

Talking about the "wheel power" of the modern generation of loaders, it is the electronics telling the engine what to do when it's detected that the loader is in the pile digging. All the larger loaders from 980 upwards work this way as far as I'm aware. Check out the diagram below.

At 1800 RPM the converter can absorb all the torque that the engine can produce, leaving nothing for operating the hydraulics. However if you look at 1200 RPM the engine actually produces more torque than at 1800, the "Torque Rise" all engine manufacturers famously quote.

If the loader is in 1st gear forward, the bucket is on or almost on the floor the floor (as detected by the boom angle sensor), and the ground speed is less than 1mph the "Dig Strategy" is activated. The engine is commanded to go to 1200RPM which in 1st speed should be sufficient to keep the machine moving into the material. At this RPM the converter can only absrob a percentage of the engine power, leaving the rest to run the hydraulics. A lot of operators who've never run the system before equate this to the engine "lacking power" where in actual fact it's the engine doing exactly what it needs to to produce an optimum power balance between the converter and the hydraulic system.