Where and what kind of hydraulic high pressure gauge that will go up to 3000 pounds should I get? It would be just for my personal use on my marklift Model 62 manlift.

And the service manual said to connect it to a high pressure port, but I don't know where I would find the high pressure port. Would it come directly off of the main hydraulic pump? And if so, I don't know how I could get the main hydraulic pump to pressure up and see the gauge while I am operating the ground controls or aerial controls.

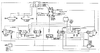

There is a gage attached to the proportional valve manifold, but I think that is for pilot pressure, which normally runs between 100 and 500 pounds. Picture attached.

And the service manual said to connect it to a high pressure port, but I don't know where I would find the high pressure port. Would it come directly off of the main hydraulic pump? And if so, I don't know how I could get the main hydraulic pump to pressure up and see the gauge while I am operating the ground controls or aerial controls.

There is a gage attached to the proportional valve manifold, but I think that is for pilot pressure, which normally runs between 100 and 500 pounds. Picture attached.