This may take a while .........

Just for all other members information Mr Kamal actually started a conversation with me instead of posting a thread for all to see, so I have the machine S/N - B9J00474. (Digressing a bit here but I have been in contact with the Admins to please post something to make it clearer to all new members how to create a thread instead of posting on their profile page or starting conversations.)

My first question is, do you have a record of the software Part Numbers that are currently installed in all the ECMs on this grader..? I see it was built in March 2008. There have been many software upgrades since then, some of which, according to the no less than

five Service Magazine articles between 2009 & 2013, were specifically targeted at the E192 Steering Event amongst others.

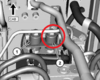

Also I suggest to take a look at the condition of the spherical bearings that mount the inside end of the steering cylinders (the 2 holes in the illustration below) for play. If there is any visible movement of the bearing when you move the steering from side to side then the measurement of the bore in the bracket needs to be looked at. Wear in that particular bearing and the (green) bracket into which it mounts has been a problem on every M Series grader I've ever come into contact with.