-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Case 580 SK Turbo parking brake won't set and question on fluids - newbie!

- Thread starter cmrsf1

- Start date

alrman

Senior Member

- Joined

- Jun 20, 2009

- Messages

- 3,308

- Location

- QLD Australia

- Occupation

- Diesel Fitter;Small Business Owner;Cleaner

Welcome to HEF @Case580k

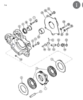

Yes you can, lift the rubber boot on the cable at the transmission housing - you will see a locknut (19mm) loosen it & use a 10mm on the machined flats on the cable end to unscrew the threaded end of the cable from the internal brake actuator.Hello, Is it possible to replace the parking brake cable on a Case 580k without disassembling the other parts of the brake? Like removing the cover etc.. I have this type of brake system:

NorwegianFarmerSon

Member

Hello, Is it possible to replace the parking brake cable on a Case 580k without disassembling the other parts of the brake? Like removing the cover etc.. I have this type of brake system: View attachment 244993

Hello,

Correct as @alrman explained. It was stuck on there pretty tight when I disassembled mine, but it will give in

I attached some pictures that show some of the work I did and most importantly it shows how the threaded end of the cable and brake actuator goes together.

NorwegianFarmerSon

Member

NorwegianFarmerSon

Member

Welcome to HEF @Case580k

Yes you can, lift the rubber boot on the cable at the transmission housing - you will see a locknut (19mm) loosen it & use a 10mm on the machined flats on the cable end to unscrew the threaded end of the cable from the internal brake actuator.

Thank you. I removed the cable fairly easily. The inner part of it was stuck. I cleaned it and rotated with a cordless screwdriver so the rust came out. I didn't replace it as it moves now smoothly.

Hi, Sorry for this question here but it is still 580k related.

What would you do with cracks on the swing tower? Especially at the handle of the boom cylinder, I have one small crack on it but can't be sure how deep it is. Welding is not recommended but getting a new or a used in good shape is almost impossible here.

What would you do with cracks on the swing tower? Especially at the handle of the boom cylinder, I have one small crack on it but can't be sure how deep it is. Welding is not recommended but getting a new or a used in good shape is almost impossible here.

Willie B

Senior Member

Welcome to HEF cmrsf1!

It is very important to repair the operation of the park brake. Apart from the safety issues - it is destroying your transmission.

When the linings are worn away the metal disc grinds away the cast iron actuator, putting iron filings into your oil. :yup

You need to drain the oil from the transmission to carry out the repair. While the oil is out remove the suction hose & clean out the screen - this will indicate any level of contamination.

The diagram shows a 2wd version. If yours is 4wd, the small transfer casing is in place of the cover. If it is 4wd check the fingers for the selector fork- they will likely be worn & need replacement.

Clean & dry all mating surfaces thoroughly & assemble using Loctite 515.

Regarding your oil - you need to use a transmission oil designed for wet brake operation. TCH or an equivalent is not to be used.

Personally I always use Case Hytrans with the brake additive - available from CNH.

:drinkup

But Case specified Case TCH fluid for this application. Lately I can't buy Case TCH fluid, my dealer says use Hytran.

I once used substitute fluid labeled as equivalent. Come hard on the brakes down a steep hill, it made a noise like grinding gears.

Willie B

Senior Member

I don't think a weld will be successful.Hi, Sorry for this question here but it is still 580k related.

What would you do with cracks on the swing tower? Especially at the handle of the boom cylinder, I have one small crack on it but can't be sure how deep it is. Welding is not recommended but getting a new or a used in good shape is almost impossible here.

A friend had a Case 13 ton excavator. He tried many times to weld ductile. It'd hold only a short time.

Tinkerer

Senior Member

FWIW, there was a discussion for successfully welding that boom on another forum by professional welders.

http://www.shopfloortalk.com/forums/showthread.php?t=1677

I have been a member on that forum for many years.

http://www.shopfloortalk.com/forums/showthread.php?t=1677

I have been a member on that forum for many years.

Willie B

Senior Member

I didn't read all three pages. The procedure being suggested sounds much like one for cast iron.FWIW, there was a discussion for successfully welding that boom on another forum by professional welders.

http://www.shopfloortalk.com/forums/showthread.php?t=1677

I have been a member on that forum for many years.

They are suggesting nickel rods, Others have recommended higher numbered stainless rods.

I'd try Hastelloy, or another TIG filler I'll have to look up.

You need a gap between the faces, I'd open it up into two pieces following the crack if you can. Cut away enough to leave a 1/4" open root, Something very thick is tricky, you want access to the very root, but a 37 degree angle on each piece leaves you with a lot to fill.

I would use TIG, maybe even AC to "cook" as much of the junk out as possible. The process, after a big preheat, is to puddle in the middle of a surface & get a bond with the dirty ductile. Work your puddle outward as you go until the whole surface is coated. I'd go a bit beyond the whole surface of the break, running onto the surrounding metal a bit.

Maintain preheat all you can, repeat the process with the other half.

Now you'll understand why you removed so much metal, Place the two pieces a pit farther apart than you want the finished product, you want an open root. Weld will shrink as it cools & you'll have to line bore anyway to put bushings back in.

Fill the gap. It'll be hard to get a TIG torch in that deep, you might want stick for that. Peen often with a needle scaler.

Keep it hot after welding.

Good luck!

Meanwhile begin the search for a donor for a transplant.

Thank you for the replies. We'll try the welding but also start looking after a replacement.

The other side was repaired as well (see picture) it looks awful but it holds. Attached two pictures of the crack, not sure how deep it is.

The other side was repaired as well (see picture) it looks awful but it holds. Attached two pictures of the crack, not sure how deep it is.

Attachments

Willie B

Senior Member

It may not be visible, but it is weakened all the way through. You will end up scrapping the tractor, or finding a donor part. The attempts at patching it has had already involved NO prep. I wonder if they even ground paint off?

Nonetheless, you are welding a part under stress where fit is critical. At best, after welding you'll need machining to fit the bushing or pin back in. A good repair that MIGHT work will cost thousands, with a 70% chance of failure.

There is text cast into the part. Does it actually say ductile?

Nonetheless, you are welding a part under stress where fit is critical. At best, after welding you'll need machining to fit the bushing or pin back in. A good repair that MIGHT work will cost thousands, with a 70% chance of failure.

There is text cast into the part. Does it actually say ductile?

Thanks everyone for this thread on servicing/repairing the parking brake. One thing I would add: You do not need to drain the hydraulic fluid. Just jack up the front end of the tractor & the fluid stays in, per the service CD I purchased. And it worked for me!