thepumpguysc

Senior Member

- Joined

- Mar 18, 2010

- Messages

- 7,538

- Location

- Sunny South Carolina

- Occupation

- Master Inj.Pump rebuilder

2 things>>

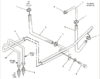

1– do u know there is a plastic filter screen IN THE PUMP.?

It’s under the large inlet nut, 15/16”

Let me know if you knew that and have checked/cleaned it..

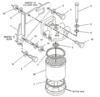

2– the filter ur running.. on that type of filter and head, U HAVE TO put the oring UP IN THE FILTER HEAD... NOT “ON” THE FILTER.!!

It looks like it goes ON the filter but it doesn’t.. it WILL choke off the fuel..

It’ll start and run until it depletes the fuel and then shut down.. and then u have to wait until it fills ..

Take the filter back down and SEE where the oring is..

Let us know about the filter in the pump inlet.. it requires instructions to remove... or bad things will happen..

1– do u know there is a plastic filter screen IN THE PUMP.?

It’s under the large inlet nut, 15/16”

Let me know if you knew that and have checked/cleaned it..

2– the filter ur running.. on that type of filter and head, U HAVE TO put the oring UP IN THE FILTER HEAD... NOT “ON” THE FILTER.!!

It looks like it goes ON the filter but it doesn’t.. it WILL choke off the fuel..

It’ll start and run until it depletes the fuel and then shut down.. and then u have to wait until it fills ..

Take the filter back down and SEE where the oring is..

Let us know about the filter in the pump inlet.. it requires instructions to remove... or bad things will happen..