Nige

Senior Member

FWIW so do I.I feel like should be running 50wt TO-4.

FWIW so do I.I feel like should be running 50wt TO-4.

I've done finals and never spent anything like that.Try closer to $10k.

Oil analysis is one of your best insurance policies, along with using quality lubricants & filters.

Cat procedure is every 500hrsHi Guys, long time lurker, first time poster. I bought a certified used 2018 304e2 with 2000hrs from Cat about a year ago. This machine was Maintained by Cat from new, always on schedule and had oil analysis done at every service. So when I got it it had probably 8 samples done from each compartment between 2018-2023. Engine an Hydraulics look great. Final drives not so much. For the first 1200hrs or so they were changing the oil in the drives every 300-400hrs. And everything looked great. Then I guess theu decided to follow the manual and go 1000hrs on the oil without changing. It’s insane that this is Cats recommendation. They hold barely a half quart, roughly $8 worth of oil if you buy it from Cat. But I digress. Ever since that sample all subsequent samples have not been good. High iron, and chromium

, and high levels of oxidation.

My SOS advisor said the machine should be brought in to cat for inspection. It’s under warranty anyways. They pulled the covers off the finals and said everything looked great. Gears looked good. I assume there wasn’t any play suggesting bearing problems. They flushed out the drives to hopefully get out any residual metal from that long service interval. I pulled a sample 77hrs later when I was doing my yearly service and still iron was high, as was oxidation.

This whole time I been running Lucas 75w140, as that’s what cat sells you and the parts guy says it’s the only oil indicated for this machine. The service department uses the same oil. My SOS advisor thought that oil may be too thick for my climate. Not sure about that, I’m in Nc so it’s very hot. But she suggested I try 30wt TODO, which is TO-4 spec oil. So I flushed the drives again using Diesel and refilled with 30wt TODO. I’ve been doing some research since then and 30wt seems pretty thin. There isn’t really even a comparable SAE viscosity for the 140 gear I’ve been runnng. 90wt gear oil is like 50wt SAE. I guess 30wt is like 80wt gear oil. Seems like the recommendation is typically a 50wt TO-4 oil for final drives.

What do you guys think? I want to get the wear metals back to normal, if that’s possible. Or atleast get them wearing at a slower rate. I’ll probably pull a sample at 50hrs and see how things look. When cat had it in for inspection they pulled a sample on the oil that had been in there for just 16hrs and everything was elevated. So 50hrs should be plenty after the flush to get a good idea if this 30wt to-4 oil is doing a better job. I’ve attached the latest oil analysis on both drives. I appreciate any insight you guys can provide.

Hitachi is 1000. Same as hydraulic oilCat procedure is every 500hrs

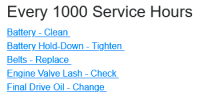

Actually for the OP's particular S/No it's recommended to change every 1000 hours, but IMO anyone who doesn't change the final drive oil every time they change the engine oil needs their head read.........Cat procedure is every 500hrs

It’s not, atleast not with a 2018 304e2. Its 1000hrs. Max id ever go is 250. For $2.75 worth of oil and a few mins of my time there’s no excuse not to.Cat procedure is every 500hrs

With cat whatever you think it should cost it typically costs double lol. A final from them is around $5k, and probably another 5k in labor. Aftermarket they can be had for $2000-2500. And probably only a few hours to swap them. But my Machine is under warranty so I’m not worried about it. Although I’d love to get them to replace them while I’m still under warranty. But they don’t want to, atleast not yet.I've done finals and never spent anything like that.

Not familiar with little CAT stuff though. On a home jobber excavator seems like just easier to keep good oil them it and run it till it makes noise.

Pull the covers off and take a look if it's really keeping a guy up at night

Seems like it'd be VERY hard to overheat them unless someone is trying to use it as a bulldozer and not as an excavator.

I’ll ask them about it. There must be some allowance for silicon. If you look at this test which was May of 2023 they said all tests appear normal. silicon was 50. Iron was 379. That doesn’t sound normal to me. But I guess iron is going to always be somewhere elevated in aa compartment like a final drive with no filter. But that still seems high on both counts.See my Post #22 above and ask your SOS person the next time you speak to them.

You would think so if the recommended oil contains silicon (still unconfirmed as of this moment) as some part of the additive package.I’ll ask them about it. There must be some allowance for silicon.

Have you tried swining the upper frame 90 degrees then using the bucket to elevate the machine so that the final drive is on an angle towards the drain plug.?I have never gotten more than about a half quart in out of them. So you figure it must be that you just can’t drain it all out, and a lot remains in the drive when you drain it.

I'm of the same mindset when it comes to final drives. Run the oil no longer than recommended and if there's no sign of water contamination, no brass flakes in the drained oil and no chunks on the magnet then put in fresh oil and go back to work. Final drives make so much fine metal during normal use I don't think they're really worth sampling.I'm surprised they bothered to oil analize that. Cost of oil analize kit far exceeds the oil cost.

Change the oil and go on with things. It is what it is.

My machine had the factory oil in the finals with over 5000hrs and I've run into that often. Same with swing gearbox.

It certainly isn't. All our maintenance procedures contained the phrase "Listed refill capacities are only approxmate. Always fill to the dipstick, sight glass, or level plug as appropriate."The fill amount in the O&M could be incorrect. That’s not uncommon.

they make it pretty fool proof, luckily. Each one is labeled, fill, drain and level. So I make sure I have it in the right orientation. I have put it at a bit of an angle but nothing crazy. I’ll try to raise it up significantly next time. But like I said when I did my diesel flush I got the exact same amount out of clean red diesel. if it was a situation where you don’t get it all out when you drain it, that diesel would have mixed with 1/4-1/2 quart of darker thick gear oil. But that’s not what came out. It was nice clean red diesel of the same thin viscosity. So this leads me to believe the capacity is not 1 quart/1/4 gallon. It’s a little over 1/2 quart. So I guess the manual is wrong.You would think so if the recommended oil contains silicon (still unconfirmed as of this moment) as some part of the additive package.

HOWEVER if you switch to an oil such as a TO-4 that has no silicon in the additive package how does the lab take account of that in their interpretation.? Surely there has to be a different approach on their part.?

Have you tried swining the upper frame 90 degrees then using the bucket to elevate the machine so that the final drive is on an angle towards the drain plug.?

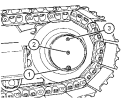

Also according to the manual there is a drain plug (1), level plug (2), and filler plug (3). It appears from the illustration that (1) and (3) are not exactly in the same position so it could affect how much oil is drained out by whether or not the final drive is correctly oriented.

View attachment 308565

I think it’s also handy for the customer justifying a repair to the dealer while under warranty. I had no idea there was any issue. Nothing felt or sounded off. Until the analysis showed me there was a potential problem. And since I had that cat had to open up the drives an inspect them. They said everything looked good. But another test that comes back red/action required or whatever and they’re going to swap or rebuild them.The data can be handy when justifying a repair to a customer, or if you have an entire fleet of similar models for analysis of predictive maintenance. Just another tool in the tool box. But sure, you can have large chunks of debri, while at the same time having a “normal” sample. Especially, if the chunks haven’t been ground into particles, yet.

I think it depends if you’re under warranty or not. My machine is. So if there’a a problem they’re going to take care of it. Luckily my cat dealer is awesome. And you’ll be hard pressed to know there’s an issue without oil analysis.I'm of the same mindset when it comes to final drives. Run the oil no longer than recommended and if there's no sign of water contamination, no brass flakes in the drained oil and no chunks on the magnet then put in fresh oil and go back to work. Final drives make so much fine metal during normal use I don't think they're really worth sampling.

I was thinking of doing samples on my crawler loaders vs spending $$ on dumping everything.I think it depends if you’re under warranty or not. My machine is. So if there’a a problem they’re going to take care of it. Luckily my cat dealer is awesome. And you’ll be hard pressed to know there’s an issue without oil analysis.

But if the machine wasn’t under warranty, I’d still sample just because that’s how I am. But what’s the point, if it shows a problem there’s nothing I can do about it. I can’t afford to pay cat service $150 to do exploratory surgery lol. Nor would I be paying to replace them when theres no issues with performance. Id just run them until I have an issue that affects the performance and then fix it.