I have an early 80s 963 that will only build 800 psi to the right track.

I have good charge pressure, no case drain pressures, left track saw 2000psi just bumping the lever a bit. the loader also works well. I have a few very very small metal flakes in the filter. How can i tell whether i have a bad pump or just a leak in the servo circuit or something?

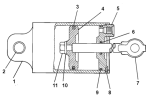

I pulled the hpcu cover, ran the machine to check for leaks under there, and manually pulled the lever to the right servo with the brakes locked.

11zn00191

I‘ve been lurking here for years and finally had a reason to post.

thanks

I have good charge pressure, no case drain pressures, left track saw 2000psi just bumping the lever a bit. the loader also works well. I have a few very very small metal flakes in the filter. How can i tell whether i have a bad pump or just a leak in the servo circuit or something?

I pulled the hpcu cover, ran the machine to check for leaks under there, and manually pulled the lever to the right servo with the brakes locked.

11zn00191

I‘ve been lurking here for years and finally had a reason to post.

thanks