Welder Dave

Senior Member

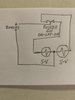

Was hoping someone could post a simple diagram how to wire a rocker switch to operate a 12 volt solenoid valve with 2 solenoids, one for raise and one for lower? Coils have 2 wires coming out and would like to hook directly from the battery. Valve is on a former plow truck that has a ton of wires and electronics that most has been chopped off and/or disconnected. Box works trouble free with jumper wires from the battery but is a pain having to get out to operate the hoist. Old system was intermittent and then stopped working all together. Instead of messing with a jungle of wires crammed into the control box would like to bypass the old system and just have a rocker switch (or 2 separate switches) in the cab for the dump box.