Rickyb1968

Well-Known Member

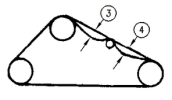

The track on the right side of dozer chatters alot when moving. All the plates are tight. The measurements are as follows. Right side between sprocket and carrier roller is 17/8”, carrier roller to front idler is 23/8”

Left side same order of measurement is 2” and 25/8”.

The left is right on the verge of being loose but the right one is jumping more. Should I tighten these up and to what?

Thanks Ricky

Left side same order of measurement is 2” and 25/8”.

The left is right on the verge of being loose but the right one is jumping more. Should I tighten these up and to what?

Thanks Ricky