-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TB 1140 Slew Problems

- Thread starter Hffhvg

- Start date

uffex

Senior Member

So I found the culprit. One of the connectors at the bottom of the control block (I don’t know what section-command) was disconnected and “plugged” on itself.

My guess is the previous owners did this because slew didn’t stop on its own, so they wouldn’t damage the ew park brake system if upper structure would drift.

Now park brake engages when running but takes at least 15-20 seconds to engage… I think theres a time delay valve at the pressure chamber for park brake? Can that be adjusted?

My guess is the previous owners did this because slew didn’t stop on its own, so they wouldn’t damage the ew park brake system if upper structure would drift.

Now park brake engages when running but takes at least 15-20 seconds to engage… I think theres a time delay valve at the pressure chamber for park brake? Can that be adjusted?

uffex

Senior Member

Good day

Sounds as if you are out of trouble.

Kind regards

Uffex

Sounds as if you are out of trouble.

Kind regards

Uffex

uffex

Senior Member

Good day

Why do you need to adjust the brake drain, those as standard do a good job?

Kind regards

Uffex

Why do you need to adjust the brake drain, those as standard do a good job?

Kind regards

Uffex

Hello.Good day

Why do you need to adjust the brake drain, those as standard do a good job?

Kind regards

Uffex

Because it takes for up to 20 seconds for slew park brake to engage. I do believe that 5 seconds is about a standard value?

uffex

Senior Member

Good day

Have you the correct grade of fluid and be sure the fluid is over 50C, that is what the manufacturers will make figures for.

Kind regards

Uffex

Have you the correct grade of fluid and be sure the fluid is over 50C, that is what the manufacturers will make figures for.

Kind regards

Uffex

I just changed the oil 5 days ago when I put the hydraulic motor back together. I put in VG46, which should be suitable for our climate according to the operators manual. I don’t know the exact temperature, but the gauge is in the green area when I am doing the testing.

Chrisso

Senior Member

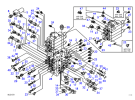

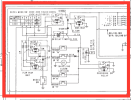

I'm guessing the time delay is electronically controlled by the "on delay timer" in Uffex's post above. I'm not seeing anything in the picture you posted (post #25) that controls time delay.So am I able to adjust the slew park brake engage time by any of these?

I'd be running through that check that Uffex posted above regarding pilot pressure in the slew circuit. Questions I'd be asking are:

Is the pilot valve (joystick) leaking, or slow to drain when centered, causing a delay in pilot pressure signal returning to zero at the main control valve (where the pressure switch is)?

Is the swing spool in the main control valve not centering properly (ie worn springs), resulting in the pressure switch still seeing pressure for say 10 seconds after you stop slewing?

Is the anti-rebound/anti-reaction/cushion valve allowing bypass, which keeps the main swing working lines under slight pressure (enough to trip the pressure switch) when it shouldn't? Is this fault only noticeable when working on a slope?

Is the pressure switch, delay timer and park brake release switch working correctly?

Lastly, what is a flip flop unit?!

I have zero experience working on this brand of machine, but answering the above questions might steer you closer to the problem.

Hello masters!

So a little update on this slew problem.

There is no more slew park brake issue, it works well now.

After changing the valve plate there was still some drift on the slope in the slew function after releasing the command (the park brake now applies after about 5 seconds until then it drifts).

The case drain test still resulted in about half a liter a second. Although the slewing got much smoother after changing the valve plate.

This result bothered me a lot so I took apart the hydraulic motor again.

I will be posting more pictures of parts in the next posts if someone more experienced would help me analyze them.

The excavator had worked for about 15 hours in between. As I checked the state of the valve plate I noticed it started developing the same wear pattern as the old one. It was minimal maybe two 0.02mm deep grooves in the center top center between left and right kidneys, but I feel that is still a lot for 15 hours. I don’t have a picture of how the new plate wore down because I already lapped it to a flat surface. I marked it on the old plate with blue color of how it looked like.

I notice that the wear on the old plate is almost symmetrical between left and right. I guess that’s why the drift is the same in both directions. And the same wear pattern is starting on the new plate, also drifting the same in both directions.

Maybe it was my mistake because I didn’t lap the new plate and the cylinder block so the two surfaces weren’t flat to each other?

I am pretty sure this is where all this oil is escaping via case drain.

Is there any other common problem that could cause some misalignment between these two components?

I am waiting for new bearings now. The needle bearing at the top felt like it had a lot of play. And the roller bearing at the bottom you could fell some “clicking” by hand when rolling and not turning smoothly.

The holes in the rotor have no significant wear on surfaces as well as the pistons. I measured them with micrometer and the clearance between them is 0.025mm. Manual says clearance of 0.04 is level of concern. Pistons also pass smoothly through.

So a little update on this slew problem.

There is no more slew park brake issue, it works well now.

After changing the valve plate there was still some drift on the slope in the slew function after releasing the command (the park brake now applies after about 5 seconds until then it drifts).

The case drain test still resulted in about half a liter a second. Although the slewing got much smoother after changing the valve plate.

This result bothered me a lot so I took apart the hydraulic motor again.

I will be posting more pictures of parts in the next posts if someone more experienced would help me analyze them.

The excavator had worked for about 15 hours in between. As I checked the state of the valve plate I noticed it started developing the same wear pattern as the old one. It was minimal maybe two 0.02mm deep grooves in the center top center between left and right kidneys, but I feel that is still a lot for 15 hours. I don’t have a picture of how the new plate wore down because I already lapped it to a flat surface. I marked it on the old plate with blue color of how it looked like.

I notice that the wear on the old plate is almost symmetrical between left and right. I guess that’s why the drift is the same in both directions. And the same wear pattern is starting on the new plate, also drifting the same in both directions.

Maybe it was my mistake because I didn’t lap the new plate and the cylinder block so the two surfaces weren’t flat to each other?

I am pretty sure this is where all this oil is escaping via case drain.

Is there any other common problem that could cause some misalignment between these two components?

I am waiting for new bearings now. The needle bearing at the top felt like it had a lot of play. And the roller bearing at the bottom you could fell some “clicking” by hand when rolling and not turning smoothly.

The holes in the rotor have no significant wear on surfaces as well as the pistons. I measured them with micrometer and the clearance between them is 0.025mm. Manual says clearance of 0.04 is level of concern. Pistons also pass smoothly through.

Attachments

There is wear on the faces of piston shoes that could probably cause some case drain but I am not sure about that. They glide smoothly on the swash plate and when I disassembled the motor it felt like they stick to the swash plate like a vacuum.

The swash plate looks like it has scratches but can’t feel any wear on it. The surface finish measures at Ra0.038 which is crazy accurate. It also rotates smoothly in the housing seat.

The play between pistons and its shoes is non existent.

The swash plate looks like it has scratches but can’t feel any wear on it. The surface finish measures at Ra0.038 which is crazy accurate. It also rotates smoothly in the housing seat.

The play between pistons and its shoes is non existent.

Attachments

Here is also a video of how the slew behaved when the new valve plate was installed.

Ignore the comments of slew park brake, the video is a month old and the park brake works fine. Uffex was right again. The oil wasn’t at the right temperature when I was testing it.

Ignore the comments of slew park brake, the video is a month old and the park brake works fine. Uffex was right again. The oil wasn’t at the right temperature when I was testing it.

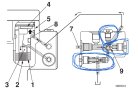

So I got the parts today.

It seems that previous owner was changing the bearings and put in a shorter needle bearing to the brake valve.

The original part from Hitachi seems 8 to 10 mm longer than the one that was installed up to now.

Could that make the shaft with the cylinder block-rotor be misaligned to the brake valve and valve-port plate? Causing this distinctive one sided wear?

It seems that previous owner was changing the bearings and put in a shorter needle bearing to the brake valve.

The original part from Hitachi seems 8 to 10 mm longer than the one that was installed up to now.

Could that make the shaft with the cylinder block-rotor be misaligned to the brake valve and valve-port plate? Causing this distinctive one sided wear?

Attachments

PROBLEM FIXED! (At least I hope)

I will just put this update here if any poor soul has similar issues.

With the slew drifting in my case the problem was in the hydraulic motor.

First I checked al the valves and poppets on the brake valve. I also checked the pressure and how it drips so I was sure the problem isn’t coming from the control valve or anywhere else (all of this stuff I learned pretty much from this forum, I appreciate all the help).

After checking the case drain it became clear where the problem was since it was overflowing abruptly.

I had the motor apart three times.

First I only changed the valve-port plate. It was in a pretty bad shape. Other components seemed okay, the pistons with the cylinder block were in a tight tolerance and pistons had no play between the shoes. By changing that part I can say the problem got 50% fixed (the drift wasn’t as apparent).

Second time I changed the bearings and the seal to the reduction gears. The needle bearing was shorter than it should be and the roller bearing wasn’t installed correctly by previous owners. I carefully inspected the shaft also for any eccentricity. There were none. The second time I also lapped the valve plate and cylinder block which I didn’t know you should do when putting it back together. This time it seemed the problem got slightly worse. The drift stayed the same but there was some pretty hard shaking and gurgling sounds at the start of the slewing command.

For the third time I ordered the new valve plate, cylinder block and the pistons. I found out that the old cylinder block was already ground town too much (compared to the new one the sliding surface was short for 1mm). Comparing the pistons the old shoes were pretty worn down at the bottom (about 0.5mm of material missing).

For now I have to say this feels solved. The drift is gone and the operation of the machine feels much smoother. The slewing command is very responsive and feels much more powerful (expected if you think that the oil was escaping before).

Thanks for all the help through this problem. I learned a lot with this one and got some basic knowledge of how my machine actually runs. Never would I ever think that I would ever see a hydraulic motor apart let alone fix one. But with all the help and information I gained through this forum I got it down.

I really appreciate that.

I will just put this update here if any poor soul has similar issues.

With the slew drifting in my case the problem was in the hydraulic motor.

First I checked al the valves and poppets on the brake valve. I also checked the pressure and how it drips so I was sure the problem isn’t coming from the control valve or anywhere else (all of this stuff I learned pretty much from this forum, I appreciate all the help).

After checking the case drain it became clear where the problem was since it was overflowing abruptly.

I had the motor apart three times.

First I only changed the valve-port plate. It was in a pretty bad shape. Other components seemed okay, the pistons with the cylinder block were in a tight tolerance and pistons had no play between the shoes. By changing that part I can say the problem got 50% fixed (the drift wasn’t as apparent).

Second time I changed the bearings and the seal to the reduction gears. The needle bearing was shorter than it should be and the roller bearing wasn’t installed correctly by previous owners. I carefully inspected the shaft also for any eccentricity. There were none. The second time I also lapped the valve plate and cylinder block which I didn’t know you should do when putting it back together. This time it seemed the problem got slightly worse. The drift stayed the same but there was some pretty hard shaking and gurgling sounds at the start of the slewing command.

For the third time I ordered the new valve plate, cylinder block and the pistons. I found out that the old cylinder block was already ground town too much (compared to the new one the sliding surface was short for 1mm). Comparing the pistons the old shoes were pretty worn down at the bottom (about 0.5mm of material missing).

For now I have to say this feels solved. The drift is gone and the operation of the machine feels much smoother. The slewing command is very responsive and feels much more powerful (expected if you think that the oil was escaping before).

Thanks for all the help through this problem. I learned a lot with this one and got some basic knowledge of how my machine actually runs. Never would I ever think that I would ever see a hydraulic motor apart let alone fix one. But with all the help and information I gained through this forum I got it down.

I really appreciate that.