skyking1

Senior Member

They removed the rotted stuff and want to put it back It was sitting on a row of half RR ties hand dug in as pilings on a cap, and (5) 6x12 x 16' notched at the ends a bit to sit over the cap. All pinned together.

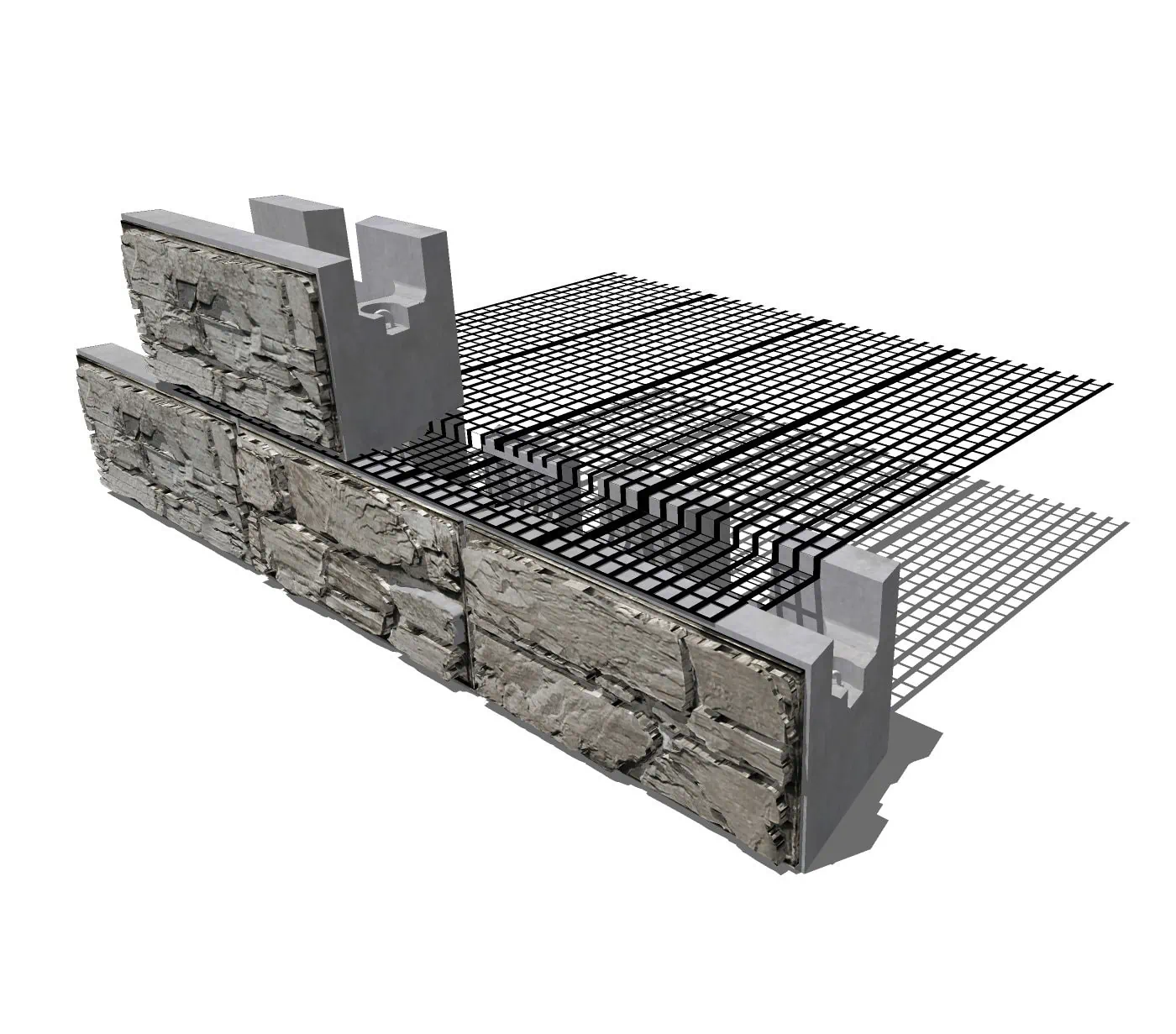

My plan is to use some magnum blocks @ 15' apart as I can set those with the mini. I have a whole stack of new looking 6x12x10' deck boards to put on.

I am going to look at some switch ties, but they are used and I would be concerned that they may sag over time. I found some real treated bridge timbers 10x18, but they are a drive and some extra $$

I think those would work with just two at 6' OC.

Planned use is a pickup truck, possibly a light trailer but the span is so short it is one at a time on it.

My plan is to use some magnum blocks @ 15' apart as I can set those with the mini. I have a whole stack of new looking 6x12x10' deck boards to put on.

I am going to look at some switch ties, but they are used and I would be concerned that they may sag over time. I found some real treated bridge timbers 10x18, but they are a drive and some extra $$

I think those would work with just two at 6' OC.

Planned use is a pickup truck, possibly a light trailer but the span is so short it is one at a time on it.