PhilDirt

Well-Known Member

I'm building a detachable root/rock rake for the bucket of my 955L. The tines will be 1.5" or 2" thick AR400. I thought I should use replaceable teeth tips on the tines but I'm now wondering if it's necessary or even advisable.

It's going to get used in a demo/clean fill site, to rake medium sized chunks of concrete and rocks out of loads of otherwise spreadable fill that are being wasted now. I also want to rake out the top 10" or so once it's at grade to remove whatever is left there. It will also be used to stack burn piles from tree removal. It's going to get steady use for 10 years or more, this is a large site, and I want it to hold up for the duration. I don't have experience with a rake like this, I'm afraid the concrete and rock will wear out the ends of the AR400 tines before I'm ready to finish the site. On the other hand, I've been told the small teeth with the rubber bushed split pins won't stay on the ends of the tines if I catch one on a root or rock while backing up. What do you guys think that have experience with this? Do I need the teeth or is straight AR400 enough? Perhaps no teeth and some hard facing weld on the tines? How sturdy are the small replaceable teeth? Like these -

I'd rather not use a bolt to hold them on, to reduce snags. It's been suggested that I could weld them on, possibly just a plug weld through the side hole.

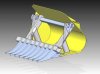

I need some advice, this is going to be my first rake. Here's a photo of what I'm designing so far.

It's going to get used in a demo/clean fill site, to rake medium sized chunks of concrete and rocks out of loads of otherwise spreadable fill that are being wasted now. I also want to rake out the top 10" or so once it's at grade to remove whatever is left there. It will also be used to stack burn piles from tree removal. It's going to get steady use for 10 years or more, this is a large site, and I want it to hold up for the duration. I don't have experience with a rake like this, I'm afraid the concrete and rock will wear out the ends of the AR400 tines before I'm ready to finish the site. On the other hand, I've been told the small teeth with the rubber bushed split pins won't stay on the ends of the tines if I catch one on a root or rock while backing up. What do you guys think that have experience with this? Do I need the teeth or is straight AR400 enough? Perhaps no teeth and some hard facing weld on the tines? How sturdy are the small replaceable teeth? Like these -

I'd rather not use a bolt to hold them on, to reduce snags. It's been suggested that I could weld them on, possibly just a plug weld through the side hole.

I need some advice, this is going to be my first rake. Here's a photo of what I'm designing so far.