This is a question for all you guys who have built a pond before, more specifically the ones who have installed a catch basin type drainage system.

I’ve got a plan on how I’m going to do this, but doesn’t hurt to ask for other opinions as I have never done this before.

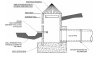

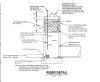

I’ve purchased a 2’x2’ precast concrete catch basin that I will have to knockout the side wall to accept my 15” double wall pipe.

Obviously I’m not going to be able to make a watertight hole between the concrete and pipe, so what do you all recommend for sealing the connection point?

In the research I’ve done, people use grout, hydraulic cement, etc., but I’m wondering which option is better or if I need to go a different way.

I’ve got a plan on how I’m going to do this, but doesn’t hurt to ask for other opinions as I have never done this before.

I’ve purchased a 2’x2’ precast concrete catch basin that I will have to knockout the side wall to accept my 15” double wall pipe.

Obviously I’m not going to be able to make a watertight hole between the concrete and pipe, so what do you all recommend for sealing the connection point?

In the research I’ve done, people use grout, hydraulic cement, etc., but I’m wondering which option is better or if I need to go a different way.