Let me give some background on my machine; I bought it with a bad final drive and pump. I replaced the final drive and had the pump rebuilt. I'm getting correct system pressure from the pump right now, but operating the boom as a compound function is very slow. When i operate just the boom it takes 8 seconds to cycle up and 8 seconds to cycle down. I pulled off the boom cylinder and inspected the inside of the barrel and rod for damage, and they look smooth as a mirror.

The travel function is also slow.

I don't want to pull apart the control valve unless I have to.

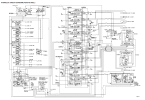

We are suspecting there is debris blocking either screens or orifices. Can someone share the hydraulic schematics on this model machine? Serial number is 9319.

The travel function is also slow.

I don't want to pull apart the control valve unless I have to.

We are suspecting there is debris blocking either screens or orifices. Can someone share the hydraulic schematics on this model machine? Serial number is 9319.