Got used machine. Haven't found owner manual yet. Pusher blade acts like it is in float mode or something. It will come up when I pull on the lever. Push down on the lever and it lowers to the ground but doesn't even try to push down or stabilize the machine. I see the sticker beside the lever, there is pictures that seem to indicate UP, DOWN, and FLOAT. The lever doesn't feel like there is any particular float mode. What am I missing?

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No down pressure on blade. Cat 303.5E.

- Thread starter ddiiggy

- Start date

skyking1

Senior Member

let up a little bit when you push the lever, you can push right past the hard setting to float.

Personally I dislike the float feature for that reason.

Personally I dislike the float feature for that reason.

I am not feeling any setting to float. All I am feeling is up or down.let up a little bit when you push the lever, you can push right past the hard setting to float.

Personally I dislike the float feature for that reason.

Nige

Senior Member

Post a Serial Number. A manual can be downloaded from the web, just need to identify the correct one.Haven't found owner manual yet.

Nige

Senior Member

Try moving the blade control lever with the machine off. You should be able to feel the Raise and Lower positions that ought to be approximately equidistant from the centre (Hold) position. Once you have got there, try pushing the lever forward beyond the Lower position which would be Float.

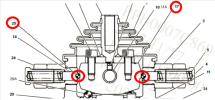

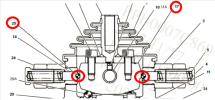

The blade control valve is shown in the illustration below. There are two spring-loaded balls/rollers (not sure which) #25 acting on a cam #17 that are designed to prevent the operator accidentally going past the Lower position and actuating the Float function while lowering the blade. It should be necessary to push the lever quite hard to get to the Float position.

The blade control valve is shown in the illustration below. There are two spring-loaded balls/rollers (not sure which) #25 acting on a cam #17 that are designed to prevent the operator accidentally going past the Lower position and actuating the Float function while lowering the blade. It should be necessary to push the lever quite hard to get to the Float position.

Finally, sort of, figured this out. Good enough, I guess.

There is one LITTLE sweet spot that does push the blade down. The lever is real easy to just push it all the way and the blade floats down. If I push the lever forward slowly, I can get it to push the blade down. There is no feel of ball or detent action to indicate anything is supposed to be happening. This could be the way it is supposed to be or something could be bonked, but I figured out how to make it work for me.

There is one LITTLE sweet spot that does push the blade down. The lever is real easy to just push it all the way and the blade floats down. If I push the lever forward slowly, I can get it to push the blade down. There is no feel of ball or detent action to indicate anything is supposed to be happening. This could be the way it is supposed to be or something could be bonked, but I figured out how to make it work for me.

Nige

Senior Member

It sounds to me as though you were pushing the lever past the DOWN position into float all the time.

Did you pull the control apart to check if the detents were actually working.?

Did you pull the control apart to check if the detents were actually working.?

Haven't taken anything apart.It sounds to me as though you were pushing the lever past the DOWN position into float all the time.

Did you pull the control apart to check if the detents were actually working.?

Nige

Senior Member

I would suggest that should be your next move. Refer to post #5 above.Haven't taken anything apart.

Also if you want help in tracking down an Operation & Maintenance Manual please post a Serial Number.

Welder Dave

Senior Member

Also make sure everything is tight on the valve spool. The bolts on the end cap (that also holds the control lever) of the control valve on my Ag tractor have come loose and not let the valve operate properly. It wasn't getting full travel one way which prevented it from going into float. Maybe you have a similar but opposite problem that puts it in float to easily??

RKY04562I would suggest that should be your next move. Refer to post #5 above.

Also if you want help in tracking down an Operation & Maintenance Manual please post a Serial Number.

I don't know what all naming options are available: Owner, Operation, Maintenance, Repair, Service...

Nige

Senior Member

Basically there are three Manuals.I don't know what all naming options are available:

1. Operation & Maintenance. Covers all aspects of operation and basic preventive maintenance tasks, fluid recommendations, etc.

2. Parts. Exactly what the name implies.

3. Service. Effectively a full workshop manual covering every aspect of machine repair, testing, troubleshooting, etc, etc. It also includes a copy of the O&M Manual.

Here are the Pubication Numbers: -

1. O&M - SEBU8746. You can download one from HERE for $75 and have it in 5 minutes. Alternatively a CD is $49 from HERE

2. Parts - Search the interweb for SEBP5957, or you can get a CD from HERE for $89.

3. Service - Search for UENR1580 but be aware they are over $1,000 new in paper form or $785 on CD.