Syleng1

Well-Known Member

Afternoon folks,

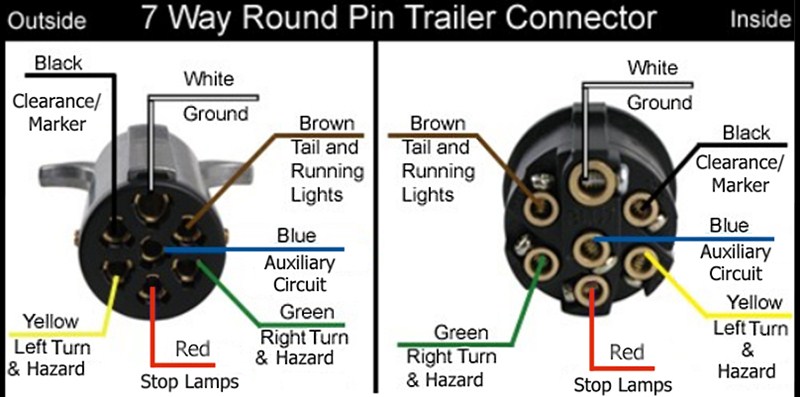

My 2022 Workmaster 70 loader tractor pulls my Bandit 200+ wood chipper very easily. But when I go out into the woods to chip brush, going down some big hills on my property the chipper pushes the tractor around a bit. (Rear tires are weighted too.) So I have on the back of the tractor a trailer plug (big rig style not RV). What I want to do is make a jumper to go from the tractor to the chipper (easy part) BUT install a manual trailer brake controller I can control with a switch because of the tractor braking system I cannot (control the chipper brakes) by installing a proper pickup truck unit nor would it survive the elements. I’m picturing a resistor or heat sink in the jumper harness to drop voltage from tractor from 14.2 to say 8vdc. Enough to engage brakes but not lock them up. Brake on chipper are excellent (almost new) to pass DOT inspection each year for road plates. I will be open to suggestions and will add a few photos to give you an idea of what I am working with. thanks Joe

So I have on the back of the tractor a trailer plug (big rig style not RV). What I want to do is make a jumper to go from the tractor to the chipper (easy part) BUT install a manual trailer brake controller I can control with a switch because of the tractor braking system I cannot (control the chipper brakes) by installing a proper pickup truck unit nor would it survive the elements. I’m picturing a resistor or heat sink in the jumper harness to drop voltage from tractor from 14.2 to say 8vdc. Enough to engage brakes but not lock them up. Brake on chipper are excellent (almost new) to pass DOT inspection each year for road plates. I will be open to suggestions and will add a few photos to give you an idea of what I am working with. thanks Joe

My 2022 Workmaster 70 loader tractor pulls my Bandit 200+ wood chipper very easily. But when I go out into the woods to chip brush, going down some big hills on my property the chipper pushes the tractor around a bit. (Rear tires are weighted too.)

So I have on the back of the tractor a trailer plug (big rig style not RV). What I want to do is make a jumper to go from the tractor to the chipper (easy part) BUT install a manual trailer brake controller I can control with a switch because of the tractor braking system I cannot (control the chipper brakes) by installing a proper pickup truck unit nor would it survive the elements. I’m picturing a resistor or heat sink in the jumper harness to drop voltage from tractor from 14.2 to say 8vdc. Enough to engage brakes but not lock them up. Brake on chipper are excellent (almost new) to pass DOT inspection each year for road plates. I will be open to suggestions and will add a few photos to give you an idea of what I am working with. thanks Joe

So I have on the back of the tractor a trailer plug (big rig style not RV). What I want to do is make a jumper to go from the tractor to the chipper (easy part) BUT install a manual trailer brake controller I can control with a switch because of the tractor braking system I cannot (control the chipper brakes) by installing a proper pickup truck unit nor would it survive the elements. I’m picturing a resistor or heat sink in the jumper harness to drop voltage from tractor from 14.2 to say 8vdc. Enough to engage brakes but not lock them up. Brake on chipper are excellent (almost new) to pass DOT inspection each year for road plates. I will be open to suggestions and will add a few photos to give you an idea of what I am working with. thanks Joe