kerry2zno

Member

Cat 953C 2ZN

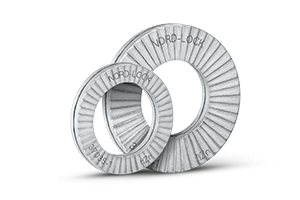

I am having trouble keeping the mounting bolts on my bottom rollers tight. Last fall I took both roller frames off and replaced all broken bolts. Every bolt was replaced with new Cat bolts. Bolts from the rear track guides to the front idler come loose.

Any ideas on what to do?

I am having trouble keeping the mounting bolts on my bottom rollers tight. Last fall I took both roller frames off and replaced all broken bolts. Every bolt was replaced with new Cat bolts. Bolts from the rear track guides to the front idler come loose.

Any ideas on what to do?