Afternoon All,

Newbie here. Just hired a Bobcat 2.75 Tonne E272 for a week last Monday and moving in some woodland to clear it of bamboo, a bamboo stick about 15-20 mm in diameter got caught in the hydraulic pipes and pulled/ pushed(?) the projecting threaded pipe

coming out of the barrel at its lower end sideways and out spurts the hydraulic oil! There is a crack about 15 mm long. Managed to get off the top pin easily - just took out the circlip and out it came. There are two pins in the bottom bracket (upper and lower) and the upper slides in and out no problem. BUT.. the bottom one I can only get to move about 1 mm in either direction.

coming out of the barrel at its lower end sideways and out spurts the hydraulic oil! There is a crack about 15 mm long. Managed to get off the top pin easily - just took out the circlip and out it came. There are two pins in the bottom bracket (upper and lower) and the upper slides in and out no problem. BUT.. the bottom one I can only get to move about 1 mm in either direction.

I need the cylinder off to try to weld up the crack. Have tried: releasing agent, nylon hammer and drift, club hammer and chunk of wood, sledge hammer and wood then sledge hammer direct! No joy. I even considered (even though all sense said that it was impossibly unlikely) considering undoing the grease nipple in case the thread had been over extended into the pin and was restricting its movement but then discounted it. Am now considering a blow lamp on the housing to expand it and release any restricting gunge.

I need the cylinder off to try to weld up the crack. Have tried: releasing agent, nylon hammer and drift, club hammer and chunk of wood, sledge hammer and wood then sledge hammer direct! No joy. I even considered (even though all sense said that it was impossibly unlikely) considering undoing the grease nipple in case the thread had been over extended into the pin and was restricting its movement but then discounted it. Am now considering a blow lamp on the housing to expand it and release any restricting gunge.

Questions: IS there any hidden form of restriction such as a grub screw?

Is there a preferred side of it to come out? the threaded rod/bolt stop side (left as you sit in the cab) or the other way?

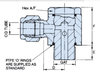

It seems to me that the connection pipe off the cylinder "should" rightly be a threaded connection but for the life of me it looks as if it is all one piece and sensible use of a spanner to try and "unscrew" it shows it does not think of budging. Does anyone know if this is a one piece item of the thread is so well hidden that one cannot see it?

Any other suggestions?

Newbie here. Just hired a Bobcat 2.75 Tonne E272 for a week last Monday and moving in some woodland to clear it of bamboo, a bamboo stick about 15-20 mm in diameter got caught in the hydraulic pipes and pulled/ pushed(?) the projecting threaded pipe

coming out of the barrel at its lower end sideways and out spurts the hydraulic oil! There is a crack about 15 mm long. Managed to get off the top pin easily - just took out the circlip and out it came. There are two pins in the bottom bracket (upper and lower) and the upper slides in and out no problem. BUT.. the bottom one I can only get to move about 1 mm in either direction.

coming out of the barrel at its lower end sideways and out spurts the hydraulic oil! There is a crack about 15 mm long. Managed to get off the top pin easily - just took out the circlip and out it came. There are two pins in the bottom bracket (upper and lower) and the upper slides in and out no problem. BUT.. the bottom one I can only get to move about 1 mm in either direction.

Questions: IS there any hidden form of restriction such as a grub screw?

Is there a preferred side of it to come out? the threaded rod/bolt stop side (left as you sit in the cab) or the other way?

It seems to me that the connection pipe off the cylinder "should" rightly be a threaded connection but for the life of me it looks as if it is all one piece and sensible use of a spanner to try and "unscrew" it shows it does not think of budging. Does anyone know if this is a one piece item of the thread is so well hidden that one cannot see it?

Any other suggestions?