Hello,

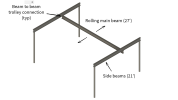

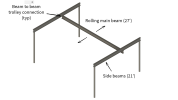

I have a small shop crane I want to build. Ive ran the calcs on a 2ton load across this 27' span and determined I need a w12x40 main beam. My big question is how are these small crane beams typically connected? Im thinking using a 3 ton trolley on either side and running the load pin through the butt plate welded on a beam.

This is a very small scale, manual chain hoist setup I move truck cabs with in a residential shop. 2tons is overkill the typical lift is 800#. I want it to cover the whole bay so the premade workstation cranes dont look to be a good fit.

I have a small shop crane I want to build. Ive ran the calcs on a 2ton load across this 27' span and determined I need a w12x40 main beam. My big question is how are these small crane beams typically connected? Im thinking using a 3 ton trolley on either side and running the load pin through the butt plate welded on a beam.

This is a very small scale, manual chain hoist setup I move truck cabs with in a residential shop. 2tons is overkill the typical lift is 800#. I want it to cover the whole bay so the premade workstation cranes dont look to be a good fit.