Your machine serial No. is YH02-01307 (not TH02...!!!). The model of the machine is SK135SRLC-1E.

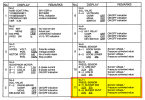

You should go to the service diagnostics menu and check item number 11 (bucket sensor); Item number 14 (pump pressure sensor P1) and item number 24 (pump P1- Propo valve) to see how those parameters change when you operate the bucket.

View attachment 305522

View attachment 305521

View attachment 305520

Good evening

I have driven the machine and carried out as you advised as below . I have also found that the tracking on each track is slow unless you operate another service then it speeds up track times at full rpm are left 30.13 seconds and right 30.26 seconds

Bucket sensor no 11 (not operating)

Dig 0.5v 0.0m

Dump 0.5v 0.0m

Operating no 11

Dig 4.8v 3.0m

Dump 4.9 3.0m

Pump pressure sensor no 14 (not operating )

P1 0.5v 0.1m

P2 0.4v 0.0m

Operating no 14

P1 0.5v 1.0m

P2 0.5v 0.8m

Prop valve no 24 ( not operating)

Comp 438ma 1.1m

Measure 434ma 1.1m

Operating no 24

Comp 350ma 0.6m

Measure 341ma 0.6m

Arm no 10 (not operating)

Out 0.5v 0.0m

In 0.5v 0.0m

Operating no 10

Out 4.9 3.0m

In 4.9v 3.0m

My thoughts are that seeing as the values are the same on the services that are slow would this be a pump issue . If so would you send off to be reconditioned

Many thanks for your advice/help so far