joelx777

Well-Known Member

I'm back again! I appreciate all the help I received solving my last issue with the John Deere 490e boom being weak.

My issue now is that the thumb became weak today and a couple of days ago after about an hour of operation. It would not hold my grading beam any longer. The hydraulic system was around 150 fahrenheit, so not too hot.

Thumb up seems to be fine and strong, hitting the system relief pressure of 5400. I am not sure what the pressure settings are supposed to be for the thumb, the manual doesn't say. When the machine is first turned on and the thumb is operating correctly, thumb down has a pressure of 2800.

When the issue occurs, I am only getting around 200-800 psi of pressure. I noticed the thumb hydraulic lines seem to "dance" more as well when this happens.

Here is a video demonstration of the issue:

https://photos.app.goo.gl/rYB8GBBeE3o2G3gK7

Since the boom down issue was fixed by replacing the circuit relief valve, I have had to replace a couple of hydraulic hoses that burst as well. Here is the most recent one, I am not sure if it is related to the thumb:

I am wondering if I have some sort of hydraulic system contamination as this issue is similar to the boom down issue? Hmmm...

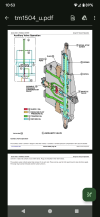

The manual doesn't say a lot about the auxiliary setup or psi settings, here is what it says about the auxiliary valve:

My issue now is that the thumb became weak today and a couple of days ago after about an hour of operation. It would not hold my grading beam any longer. The hydraulic system was around 150 fahrenheit, so not too hot.

Thumb up seems to be fine and strong, hitting the system relief pressure of 5400. I am not sure what the pressure settings are supposed to be for the thumb, the manual doesn't say. When the machine is first turned on and the thumb is operating correctly, thumb down has a pressure of 2800.

When the issue occurs, I am only getting around 200-800 psi of pressure. I noticed the thumb hydraulic lines seem to "dance" more as well when this happens.

Here is a video demonstration of the issue:

https://photos.app.goo.gl/rYB8GBBeE3o2G3gK7

Since the boom down issue was fixed by replacing the circuit relief valve, I have had to replace a couple of hydraulic hoses that burst as well. Here is the most recent one, I am not sure if it is related to the thumb:

I am wondering if I have some sort of hydraulic system contamination as this issue is similar to the boom down issue? Hmmm...

The manual doesn't say a lot about the auxiliary setup or psi settings, here is what it says about the auxiliary valve: