Scout_1969

Well-Known Member

Some Background:

Had machine approx. 2 years, changed hydraulic filters when first purchased, machine was at about 3500 hours and I have put approx. 300 hours on it. Replaced pressure control valve o-rings about 30 hours ago.

Problem:

Hydraulics began to be slow recently, and jerky. Steering doesn't seem to have full power and when starting actually turns itself with weight off front axle. Forward and reverse work fine, but I did notice when climbing a pile of dirt while piling more up it would sometimes (not often) sort of stop pulling and not stall.

Work/Troubleshooting so far:

I had someone check pressures and operated machine and he said the main hydraulic pump was bad. Took pump off and sent to rebuild shop to find out the pump was not the problem, however, they recommended a rebuild kit be installed and said it would be at 95% when done. The pump has been into before as someone numbered the 8 or so large nuts.

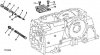

After sending out the pump, I removed the transmission screen and found metal shavings of all types and one washer, see pictures. All were removed with a magnet, some have a copper/bronze look. Since I didn't clean trans. screen when I got it, I don't know if the debris may have been from a previous failure/repair.

My plan at this point:

Final clean debris out of transmission, maybe flush with diesel or blow out with air. Put on new filters/fluid, put pump on and operate a little and change fluid and filters and clean screen and see if I get more debris and of course check operation. Repeat as necessary.

Questions:

Had machine approx. 2 years, changed hydraulic filters when first purchased, machine was at about 3500 hours and I have put approx. 300 hours on it. Replaced pressure control valve o-rings about 30 hours ago.

Problem:

Hydraulics began to be slow recently, and jerky. Steering doesn't seem to have full power and when starting actually turns itself with weight off front axle. Forward and reverse work fine, but I did notice when climbing a pile of dirt while piling more up it would sometimes (not often) sort of stop pulling and not stall.

Work/Troubleshooting so far:

I had someone check pressures and operated machine and he said the main hydraulic pump was bad. Took pump off and sent to rebuild shop to find out the pump was not the problem, however, they recommended a rebuild kit be installed and said it would be at 95% when done. The pump has been into before as someone numbered the 8 or so large nuts.

After sending out the pump, I removed the transmission screen and found metal shavings of all types and one washer, see pictures. All were removed with a magnet, some have a copper/bronze look. Since I didn't clean trans. screen when I got it, I don't know if the debris may have been from a previous failure/repair.

My plan at this point:

Final clean debris out of transmission, maybe flush with diesel or blow out with air. Put on new filters/fluid, put pump on and operate a little and change fluid and filters and clean screen and see if I get more debris and of course check operation. Repeat as necessary.

Questions:

- Is flushing or blowing out a good idea?

- Am I on the right track? Or what other troubleshooting might I try?

- Where is the charge pump? I cannot find it by that name in my parts book or online, a picture and/link/part number would be appreciated.

- Are there any links, pictures or videos on how to split a machine?

- I guess if I split the machine, it probably a good time to inspect/change the clutch brakes? Any other things?

- What do the metal shavings look like they are from? The slotted washer?