-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Had new hydraulic rods made

- Thread starter LN Pipeline

- Start date

Nige

Senior Member

It's not what you see on the surface IMO, it's what was underneath that in the way of prep and how the rod/eye joint was engineered. Ask them what sort of weld groove they used on the joint. The eyes appear to be the originals, just with new rods. Is that correct.?

What type/size of machine and cylinder are these rods going to be used on.?

What type/size of machine and cylinder are these rods going to be used on.?

LN Pipeline

Well-Known Member

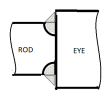

Yes, eyes were cut off old rods and welded on the new ones. Based on the dozen or so rods I’ve had made in the past, I was expecting something similar to the image below, where a noticeable bevel was cut, welded, and machined back down. The majority of the area where the eye and rod met was welded together, rather than just a bead on the surface, which is how these two new rods appear to be.

They did send me home with the old rods. After inspecting them, it looks like they may have built them similar to the factory. The picture below does not show much of a groove cut prior to welding. I expected more than this.

I was concerned that they may have done an unsatisfactory job, but that might not be the case.

These rods are 2” diameter and for a 54000 pound Tesmec trencher. One is for a stabilizer, the other raises and lowers the crumbshoe over the end of the trencher chain.

They did send me home with the old rods. After inspecting them, it looks like they may have built them similar to the factory. The picture below does not show much of a groove cut prior to welding. I expected more than this.

I was concerned that they may have done an unsatisfactory job, but that might not be the case.

These rods are 2” diameter and for a 54000 pound Tesmec trencher. One is for a stabilizer, the other raises and lowers the crumbshoe over the end of the trencher chain.

Welder Dave

Senior Member

It looks like there must have been a bevel on the original ones but it might have been uneven. The new ones were done with pretty hot Mig but a little inconsistent. I can't tell for sure but looks like there could be slight undercut on the rod. Kind of looks like there was a bevel and they filled it with 1 pass or went too slow on the cap. Would have been better to do a 2 pass side by side cap at a faster travel/rolling speed. Too much build up can be just as bad as undercut because it creates a notch where a crack could start. They might not have a had a lathe to turn the weld down like on the old rods. Notice how the originals were machined with a nice round transition with no square edges. However even the originals appear to have poor fusion in the root. You shouldn't see such a distinct line like that. There's also a couple pin holes that would fail on a pipe test. I'd rate the repaired rods OK but not great. They could have done a nicer job and at least cleaned them with a wire brush. There's still silicon pockets and spatter. Hopefully they got good penetration. They should have had a little preheat too if 2" thick but penetration is the most important. There is over 6" weld around the rod so they should be OK.

Welder Dave

Senior Member

Maybe they were originally and that's why the line is so distinct?? Lots of ends are just welded though and rarely fail. It all depends on how they were prepped for welding.

This reason alone tells me they aren't welded heavy enough.These rods are 2” diameter and for a 54000 pound Tesmec trencher

Welder Dave

Senior Member

What was the reason for new rods? The eye's don't look like they were the problem.

Nige

Senior Member

Back to my earlier question regarding what sort of groove was used to prep the rod for welding.This reason alone tells me they aren't welded heavy enough.

For a 2" diameter rod I would have thought a J-groove at least 1/4" wide x 1/2" deep, followed by a 1/4" 45-deg fillet once the groove was full of weld. Something along the lines of the sketch below.

LN Pipeline

Well-Known Member

What was the reason for new rods? The eye's don't look like they were the problem.

Both rods had severe blemishes in the chrome. The rams needed resealed, and it would have been a waste of time to reseal with the damages rods.

This reason alone tells me they aren't welded heavy enough.

I was going to take them back and tell them to build them right, but after looking at the cut ends of the factory rod, it looks like they built them the same. I’ll probably just put them together and use them. They charged me plenty for what I got.

LN Pipeline

Well-Known Member

Back to my earlier question regarding what sort of groove was used to prep the rod for welding.

For a 2" diameter rod I would have thought a J-groove at least 1/4" wide x 1/2" deep, followed by a 1/4" 45-deg fillet once the groove was full of weld. Something along the lines of the sketch below.

I’ll call and ask, but I doubt I will get valuable information. I’ve dealt with the place quite a bit, and there is always some issue. I had them fix a blemish in another rod a few years ago, and the machinist mushed the threads for the grease zerk when he put the eye in the lathe. Rather than fixing the threads, or even telling me about it, he sent it back to me with no zerk and mushed threads, and I’m 90 miles from anyone that had the right metric tap to fix it.

So whatever that machinist tells me over the phone probably won’t have any credibility.

Judging by the size of the single visible weld bead, I very much doubt there was a 1/2” deep groove.

Coaldust

Senior Member

- Joined

- May 9, 2011

- Messages

- 3,355

- Location

- North of the 60

- Occupation

- Cargo Tanks, ULSD, RUG, Methanol, LPG

I don’t have anything to add that hasn’t been said. They are probably a better machine shop vs a welding shop. Machinists that are trying to weld. Which is probably better than a welder trying to machine? IDK ?

cfherrman

Senior Member

Well I can't weld or machine

Jimbo

Well-Known Member

Similarly:

The difference between a welder and a rancher.......

A welder doesn't think he can ranch

The difference between a welder and a rancher.......

A welder doesn't think he can ranch

Welder Dave

Senior Member

Hopefully there was a groove and at least 2 passes as well as some preheat. 1st pass to get good penetration and 2nd pass to fill and and get good fusion wider out. Try to fill a big groove in 1 pass doesn't give near the same strength and has a much coarser grain structure. It's very unprofessional to not even clean the weld up too. Being a machine shop, it should have been a piece of cake for them to turn the weld down like the original leaving no potential stress risers.

Welder Dave

Senior Member

It depends on the weld. If there's too much build up that leaves a notch effect at toe of the weld is where a crack could potentially start. Generally you want the weld reinforcement about the thickness of a dime. It can be a little more but not right at the toe. Pics. can distort things so it's hard to tell exactly if the welds have undercut or too much build up. Even the machined portion on the original weld looks to have left some reinforcement.