raistlin

Member

Checked out all ground and ariel systems; all systems check out except Drive system.

Problem: When forward drive engaged, booms moves and turns.

When reverse drive is engaged fluid comes out of drive motor end seals (assuming from over pressure relief).

When controls are released fluid still leaks slowly- when engine is shutoff fluid stops.

*Swapped solenoid drive heads and leads; no change.

*Checked hyd shuttle valve and it was clean.

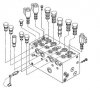

*Checked all three drive manifold solenoid valves and they were clean/ solenoids all had correct polarity and all 3 had similar resistance.

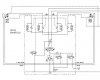

Does anyone have a hydraulic schematic for the 2wd Drive manifold?

Problem: When forward drive engaged, booms moves and turns.

When reverse drive is engaged fluid comes out of drive motor end seals (assuming from over pressure relief).

When controls are released fluid still leaks slowly- when engine is shutoff fluid stops.

*Swapped solenoid drive heads and leads; no change.

*Checked hyd shuttle valve and it was clean.

*Checked all three drive manifold solenoid valves and they were clean/ solenoids all had correct polarity and all 3 had similar resistance.

Does anyone have a hydraulic schematic for the 2wd Drive manifold?