Hi, watglen, Dozerboy makes a correct assessment. There are just too many variables to come up with a plan that works all the time. Lay a piece of paper on your desktop. Turn it 90 deg. from the typical portrait position to landscape so that the long edges are top and bottom. That approximates the pile. Mark the top "North", left "West", bottom "South", and right hand edge "East". Coal feeders are spread along the lower (southern) edge. The rail facility is parked midway down the right hand "East" edge. There's another big feeder on the left hand edge of the paper.

We have a relatively small Krupp stacker-reclaimer (relatively small compared to some of the monsters I've seen on the internet) that runs on tracks all along the bottom (South) edge of the piece of paper. It can reclaim some of the coal, or stack out over the feeders.

The rail facility's output belt is a radial stacker. When the situation permits, the radial stacker is swung into a position where we can run coal directly into the plant. Whoo-hoo! Or the output from the radial stacker can be fed to the Krupp, which can at least stack the coal closer to the West end of the pile instead of having to doze it all the way over there.

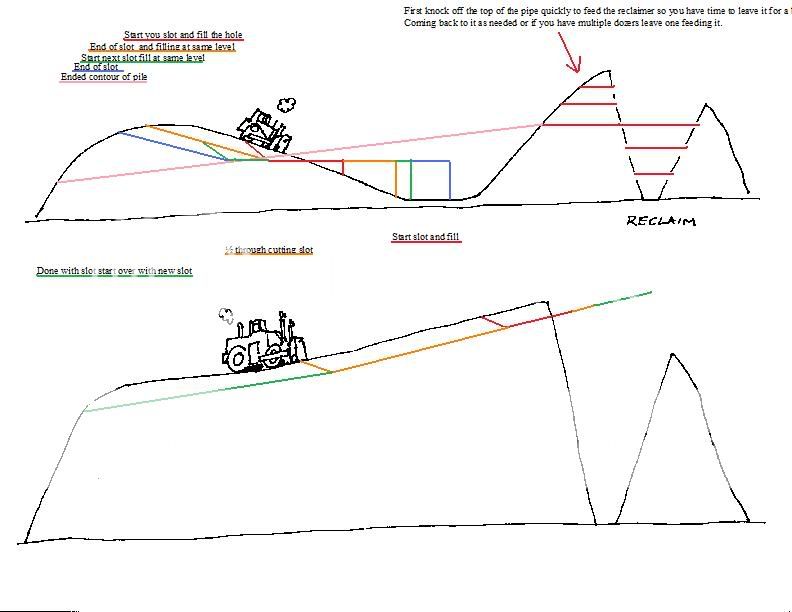

Regardless of the options we have to belt the coal, it sure seems like most of the coal gets handled. It's pushed west, from the big radial stacker on the right hand edge, out into the center of the coal pile, then very often we have to push it roughly 90 degrees from the original push to get the coal into the reclaims along south edge.

Apparently the contract with the railroad makes it difficult to adjust the deliveries week by week. Sometimes the boilers are down and the coal just keeps coming and we're stacking it way up high along the northern edge of the pile because the south and center of the pile's full. Sometimes they cut back the trains too much and we bring the entire northern edge of the coal pile south to the feeders and everyone starts freakin that we're gonna run out.

Acivil is right to some extent. It's certainly cheaper to belt the coal than push it, once the coal is on a belt. If the railcar deliveries were down to a science, and there was never a need to store extra coal, I'm sure the bosses would be happy to fire all of us and sell the dozers. Believe me, it's been discussed. They brought in expensive consultants who came up with some bizarre schemes that had belts and towers and stackers all over the place. But it always came down to no matter how many belts and stackers and reclaims you built, there would always be some handling of coal. Spending millions and millions of dollars building lots of structures in order to get rid of a few dozers apparently never penciled out.

diggerop, thanks for the returned sketch. Can you explain the comment about rubber-tire (oops, rubber-tyred) dozers not being allowed on coal? How come??