JfitzCat

Member

Hi Guys, long time lurker, first time poster. I bought a certified used 2018 304e2 with 2000hrs from Cat about a year ago. This machine was Maintained by Cat from new, always on schedule and had oil analysis done at every service. So when I got it it had probably 8 samples done from each compartment between 2018-2023. Engine an Hydraulics look great. Final drives not so much. For the first 1200hrs or so they were changing the oil in the drives every 300-400hrs. And everything looked great. Then I guess theu decided to follow the manual and go 1000hrs on the oil without changing. It’s insane that this is Cats recommendation. They hold barely a half quart, roughly $8 worth of oil if you buy it from Cat. But I digress. Ever since that sample all subsequent samples have not been good. High iron, and chromium

, and high levels of oxidation.

My SOS advisor said the machine should be brought in to cat for inspection. It’s under warranty anyways. They pulled the covers off the finals and said everything looked great. Gears looked good. I assume there wasn’t any play suggesting bearing problems. They flushed out the drives to hopefully get out any residual metal from that long service interval. I pulled a sample 77hrs later when I was doing my yearly service and still iron was high, as was oxidation.

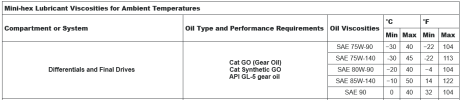

This whole time I been running Lucas 75w140, as that’s what cat sells you and the parts guy says it’s the only oil indicated for this machine. The service department uses the same oil. My SOS advisor thought that oil may be too thick for my climate. Not sure about that, I’m in Nc so it’s very hot. But she suggested I try 30wt TODO, which is TO-4 spec oil. So I flushed the drives again using Diesel and refilled with 30wt TODO. I’ve been doing some research since then and 30wt seems pretty thin. There isn’t really even a comparable SAE viscosity for the 140 gear I’ve been runnng. 90wt gear oil is like 50wt SAE. I guess 30wt is like 80wt gear oil. Seems like the recommendation is typically a 50wt TO-4 oil for final drives.

What do you guys think? I want to get the wear metals back to normal, if that’s possible. Or atleast get them wearing at a slower rate. I’ll probably pull a sample at 50hrs and see how things look. When cat had it in for inspection they pulled a sample on the oil that had been in there for just 16hrs and everything was elevated. So 50hrs should be plenty after the flush to get a good idea if this 30wt to-4 oil is doing a better job. I’ve attached the latest oil analysis on both drives. I appreciate any insight you guys can provide.

, and high levels of oxidation.

My SOS advisor said the machine should be brought in to cat for inspection. It’s under warranty anyways. They pulled the covers off the finals and said everything looked great. Gears looked good. I assume there wasn’t any play suggesting bearing problems. They flushed out the drives to hopefully get out any residual metal from that long service interval. I pulled a sample 77hrs later when I was doing my yearly service and still iron was high, as was oxidation.

This whole time I been running Lucas 75w140, as that’s what cat sells you and the parts guy says it’s the only oil indicated for this machine. The service department uses the same oil. My SOS advisor thought that oil may be too thick for my climate. Not sure about that, I’m in Nc so it’s very hot. But she suggested I try 30wt TODO, which is TO-4 spec oil. So I flushed the drives again using Diesel and refilled with 30wt TODO. I’ve been doing some research since then and 30wt seems pretty thin. There isn’t really even a comparable SAE viscosity for the 140 gear I’ve been runnng. 90wt gear oil is like 50wt SAE. I guess 30wt is like 80wt gear oil. Seems like the recommendation is typically a 50wt TO-4 oil for final drives.

What do you guys think? I want to get the wear metals back to normal, if that’s possible. Or atleast get them wearing at a slower rate. I’ll probably pull a sample at 50hrs and see how things look. When cat had it in for inspection they pulled a sample on the oil that had been in there for just 16hrs and everything was elevated. So 50hrs should be plenty after the flush to get a good idea if this 30wt to-4 oil is doing a better job. I’ve attached the latest oil analysis on both drives. I appreciate any insight you guys can provide.