Hello, I have a JD 310C hoe that is an early production VIN. I recently purchased it, during the check out the brake pedals were rock hard with no brakes. The seller stated they were blocked off and he would be fixing the brakes. The next week he called and said it was ready and dropped it off. The brakes were working unloading it off the trailer. After driving it to the barn, approximately ¼ mile the unit starting squawking horribly and wouldn’t hardly get up the hill in 1st.

I shut down and went back at it that weekend, started and worked fine, by the time I got it to the work area it was squawking again and would hardly pull. I called the fellow and received non-descript feedback…. From his sales pitch he had replaced the rear brakes and they were ok, from my inspection after the fact I see no indication the axle housings were removed.

So, I removed the brake lines at the brake valve/master cylinder and drove the unit around the field for 20 minutes with no concerns. Reconnected, bled per manual and the brakes worked great a few times then the pedal became hard right at the top again and the brakes started dragging. I removed the lines again and all was well.

I considered that the brake valve was leaking/bypassing internally building up pressure, but wrapping it in a bag and working the hoe shows no build-up of fluid so I don’t think the valve is leaking internally, looks like a spring loaded check ball would manage the return bleed and I can't imagine that it is seized, anything is possible....

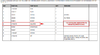

I reviewed the manual and found there is an external brake piston adjustment, 3 screws in each axle housing and considered maybe he did replace the discs and there were too tight. Well, the screws in these axle housing are not at all like the manual, they are just short O-ring cap screws effectively that when removed allows the hydraulic oil to leak out, press the brake pedal on the corresponding side and it squirts fluid out properly so I'm barking up the right tree, but there is no adjustment pin and locknut here to set the piston internal clearance.

The axle fluid was nasty, on a lark I got the fluid hot and drained the axle oil thinking perhaps he had regular gear lube, it was quite thin so likely not but was black, smelly, and full of very fine metal powder.

I refilled with hy-gard and while the initial result seems better I still feel a drag when hot and believe as time allows me to use the machine the brakes will again lock up/seize.

So my questions are;

Does anyone from back in the day know why the brake piston adjustment screws are not what is listed in the manual?

Anyone have an idea about the brake drag?

Could the fine metal powder be an indication that the discs are shot and metal to metal and the drag is being created by that related to heat, or is this normal for an old machine with wet brakes?

Is there any way to inspect the brake condition without removal of the axle housing?

I’m not scared of fixing anything on this machine but time is limited and if it is down for repairs it is not being used. I have a decent amount of hoe work that I can do while I learn about this but will reach a point where I need the loader and with the terrain I have not having brakes will be unsafe.

I shut down and went back at it that weekend, started and worked fine, by the time I got it to the work area it was squawking again and would hardly pull. I called the fellow and received non-descript feedback…. From his sales pitch he had replaced the rear brakes and they were ok, from my inspection after the fact I see no indication the axle housings were removed.

So, I removed the brake lines at the brake valve/master cylinder and drove the unit around the field for 20 minutes with no concerns. Reconnected, bled per manual and the brakes worked great a few times then the pedal became hard right at the top again and the brakes started dragging. I removed the lines again and all was well.

I considered that the brake valve was leaking/bypassing internally building up pressure, but wrapping it in a bag and working the hoe shows no build-up of fluid so I don’t think the valve is leaking internally, looks like a spring loaded check ball would manage the return bleed and I can't imagine that it is seized, anything is possible....

I reviewed the manual and found there is an external brake piston adjustment, 3 screws in each axle housing and considered maybe he did replace the discs and there were too tight. Well, the screws in these axle housing are not at all like the manual, they are just short O-ring cap screws effectively that when removed allows the hydraulic oil to leak out, press the brake pedal on the corresponding side and it squirts fluid out properly so I'm barking up the right tree, but there is no adjustment pin and locknut here to set the piston internal clearance.

The axle fluid was nasty, on a lark I got the fluid hot and drained the axle oil thinking perhaps he had regular gear lube, it was quite thin so likely not but was black, smelly, and full of very fine metal powder.

I refilled with hy-gard and while the initial result seems better I still feel a drag when hot and believe as time allows me to use the machine the brakes will again lock up/seize.

So my questions are;

Does anyone from back in the day know why the brake piston adjustment screws are not what is listed in the manual?

Anyone have an idea about the brake drag?

Could the fine metal powder be an indication that the discs are shot and metal to metal and the drag is being created by that related to heat, or is this normal for an old machine with wet brakes?

Is there any way to inspect the brake condition without removal of the axle housing?

I’m not scared of fixing anything on this machine but time is limited and if it is down for repairs it is not being used. I have a decent amount of hoe work that I can do while I learn about this but will reach a point where I need the loader and with the terrain I have not having brakes will be unsafe.