My d8 14a starter motor won't engage.

It started acting up about the first day, only turning the engine over 50% the time. When it would act up. I would shut it off, go through starting sequence and it would engage and start just fine. Trying to limp it through the project, I delt with it until today.

I removed covers for clutch and hi/low transmission, adjusted the clutch for the 100 lb snap in per operators manual.

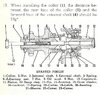

With a mirror and scope it looks like the trans is functioning normally, no broken, or chipped teeth, starting motor spins the gears all the way down to the lowest shaft in both hi/low.

I thought it might be a flywheel tooth. I can grab the engine fan and turn the main engine over to many different spots with same result.

What lies between the lower output shaft in the transmission and the flywheel, a pinion that is possibly stuck?

Any advice is appreciated.

It started acting up about the first day, only turning the engine over 50% the time. When it would act up. I would shut it off, go through starting sequence and it would engage and start just fine. Trying to limp it through the project, I delt with it until today.

I removed covers for clutch and hi/low transmission, adjusted the clutch for the 100 lb snap in per operators manual.

With a mirror and scope it looks like the trans is functioning normally, no broken, or chipped teeth, starting motor spins the gears all the way down to the lowest shaft in both hi/low.

I thought it might be a flywheel tooth. I can grab the engine fan and turn the main engine over to many different spots with same result.

What lies between the lower output shaft in the transmission and the flywheel, a pinion that is possibly stuck?

Any advice is appreciated.