FlintHillsDiesel

Member

Have a friend of mine with D6R 5LN.

He went through entire engine cooling system, water pump, radiator, thermostat.

He wanted me to look at it after that, when talking with him, he said that after engine gets hot, the transmission gets hot shortly after.

Told him its likely the transmission overheating and causing the engine overheat as secondary effect.

I work mainly on Deere equipment not as familiar on theses machines.

With going through some older threads on here, we checked the Priority Valve, and it is switching between Priority and Normal mode correctly per the pressure chart.

Priority valve - 140 psi operating temp, PB on, low idle

400 psi PB off neutral low idle

140 psi - high idle PB off

140 psi - high idle service brake on

Checked the brake pressure on the left pressure tap (right side tap is missing and didn't have time to swap them).

Left brake pressure - 390 psi.

Almost 0 when service brake applied.

Too muddy around for me to run it. Friend said it will roll to a stop, it doesn't act like the brakes are dragging/warped.

Checked transmission pressure:

Transmission system pressure - 390 psi low idle - PB On

395 psi low idle PB off

415 psi high idle PB off

410 psi high idle PB off service brake on

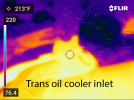

TC Inlet - Initial reading at 100 psi slowly goes down 85 psi as fluid warmed up more I assume - high idle PB off

83 psi at 175'f converter outlet to cooler.

TC Outlet - 70 psi high idle, PB off, neutral

55 psi forward 3rd gear stall, 1650 engine rpm

During stall test, the transmission temp would heat up very fast. From about 180'F to the beginning of the red happens in about 12 seconds.

I did not pay attention to how fast it cools off after.

Friend went and ran someone elses machine he knows thats a D6R LGP from same era.

Had him do a stall test after everything was at normal operating temp and said it took about 35-40 seconds to get from normal temp up to the beginning of the red on his transmission temp gauge.

At this point I'm fairly sure the torque converter is causing excessive heat. But wanted to double check to see if I am missing anything.

Can the trans pump cause that much heat that fast?

Did not get the TC inlet relief checked when oil was cold - might be wrong but I don't think this is important for the symptoms?

The torque converter outlet speed sensor was also broke apart, fixed that and cured the only active code I could see, but also think is irrelevant for the symptom as was no slippage code after fixing and doing stall test.

Also have not pulled the screens yet. Was a muddy mess that day and spent 2 hours cleaning out the compacted dirt inside the belly of the machine. What fun that was.

Thank you!!

He went through entire engine cooling system, water pump, radiator, thermostat.

He wanted me to look at it after that, when talking with him, he said that after engine gets hot, the transmission gets hot shortly after.

Told him its likely the transmission overheating and causing the engine overheat as secondary effect.

I work mainly on Deere equipment not as familiar on theses machines.

With going through some older threads on here, we checked the Priority Valve, and it is switching between Priority and Normal mode correctly per the pressure chart.

Priority valve - 140 psi operating temp, PB on, low idle

400 psi PB off neutral low idle

140 psi - high idle PB off

140 psi - high idle service brake on

Checked the brake pressure on the left pressure tap (right side tap is missing and didn't have time to swap them).

Left brake pressure - 390 psi.

Almost 0 when service brake applied.

Too muddy around for me to run it. Friend said it will roll to a stop, it doesn't act like the brakes are dragging/warped.

Checked transmission pressure:

Transmission system pressure - 390 psi low idle - PB On

395 psi low idle PB off

415 psi high idle PB off

410 psi high idle PB off service brake on

TC Inlet - Initial reading at 100 psi slowly goes down 85 psi as fluid warmed up more I assume - high idle PB off

83 psi at 175'f converter outlet to cooler.

TC Outlet - 70 psi high idle, PB off, neutral

55 psi forward 3rd gear stall, 1650 engine rpm

During stall test, the transmission temp would heat up very fast. From about 180'F to the beginning of the red happens in about 12 seconds.

I did not pay attention to how fast it cools off after.

Friend went and ran someone elses machine he knows thats a D6R LGP from same era.

Had him do a stall test after everything was at normal operating temp and said it took about 35-40 seconds to get from normal temp up to the beginning of the red on his transmission temp gauge.

At this point I'm fairly sure the torque converter is causing excessive heat. But wanted to double check to see if I am missing anything.

Can the trans pump cause that much heat that fast?

Did not get the TC inlet relief checked when oil was cold - might be wrong but I don't think this is important for the symptoms?

The torque converter outlet speed sensor was also broke apart, fixed that and cured the only active code I could see, but also think is irrelevant for the symptom as was no slippage code after fixing and doing stall test.

Also have not pulled the screens yet. Was a muddy mess that day and spent 2 hours cleaning out the compacted dirt inside the belly of the machine. What fun that was.

Thank you!!