Hunter013

Well-Known Member

2020 Kenworth T800 quad axle dump truck

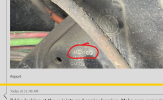

I noticed a cracked cross member while I was last under my truck. Its the carrier bearing cross member. Ill post pictures. I am waiting on a new one to get delivered and I was curious what would cause this cracking? I believe the piece is aluminum and I know the driver is not the most gentle driver I have. On the cross member closer to the motor, the bolts that connect the gussets to the cross member were loose. Would that cause play in the frame and crack the other cross member?

I noticed a cracked cross member while I was last under my truck. Its the carrier bearing cross member. Ill post pictures. I am waiting on a new one to get delivered and I was curious what would cause this cracking? I believe the piece is aluminum and I know the driver is not the most gentle driver I have. On the cross member closer to the motor, the bolts that connect the gussets to the cross member were loose. Would that cause play in the frame and crack the other cross member?