01Time

Well-Known Member

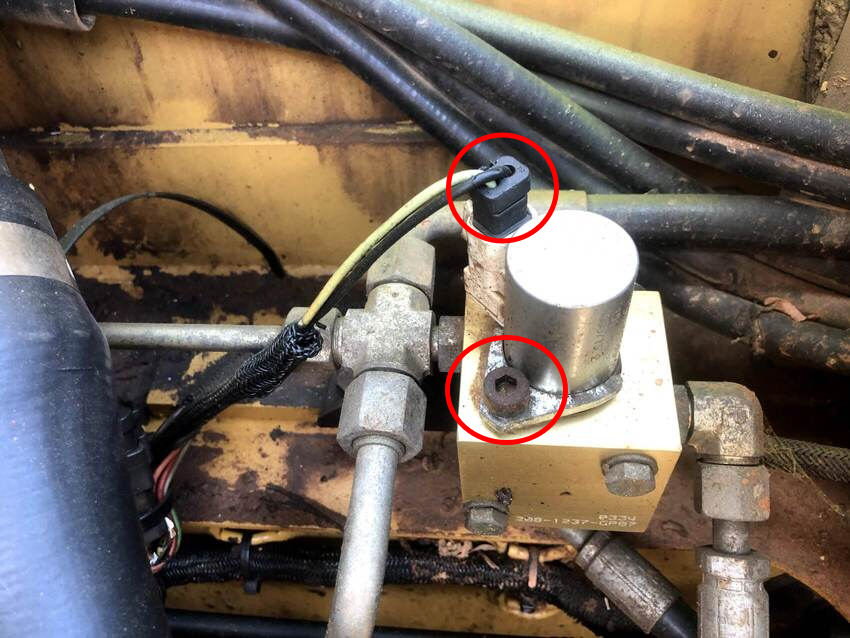

Can anyone provide guidance on replacing the Parking Brake Solenoid & Manifold on my Caterpillar 246 (s/n 5SZ07867)?

#7 in the illustration below.

Question. Why would on earth would they want to change the manifold.? It's only a block with holes drilled in it. Unless it's cracked or something like that.

You guess correctly.I'm guessing I should be able to remove the manifold to inspect it (while replacing the solenoid) and reinstall it if there are no physical defects?

$64k question. Did it fix the problem..?

Personally I wouldn't bother unless the dealer is doing any other work at the same time.I am tempted to get the pressure retested, but I feel like that would be a (possible additional) waste of money at this point.