Welder Dave

Senior Member

Or bend over more?

Actually a 6V4157 is a test group and it comes with 9 hoses with couplings and 9 gauges .They will water even more when you discover 6V-4157 is only the box with the gauges in it. There is another number (could be 6V-4158 but don’t quote me) that contains all the test hoses and couplings, adapters, pressure taps, etc, required to actually connect the test box to a machine. Last time I looked that group was about half the price of a test box. I think it’s called something like a “hose & fittings group”.

That's the one I was thinking of, and you're right it's probably a lot more than $3k for the two.The 1U5481and 82 was a popular transmission box and adaptors but I bet its twice as much.

If you have done any testing on power shift transmissions having the gauges where you can watch all of them at the same time is important ,I guess hyrastat testing is about the same so at the least mount the gauges on a bar.It would probably be worth pointing out at this stage that neither of the foregoing are absolutely essential. A handful of good quality glycerine-filled gauges of the correct ranges and just the absolutely necessary hoses & pressure taps for the OP’s machine would likely do the job just as well for maybe 1/10th of the price or less. Maybe Cmark can suggest somewhere to ask.

I'd rather spend an hour tapping the rack back and forwards then riving out the bonnets. The rack has a tiny bit of movement, so I suspect there is a plunger(s) stuck. Let's hope I can jar them loose, so I can position the rack in the centre and remove the bonnets & plungers the normal way.

I had to buy some of the test fittings they use on processor heads and the hyd. shop carries what you are talking about.Nothing wrong with that plan. Just remember to break the element retainers loose whilst the pump is still on the engine. If anyone is interested, on the "old scroll" pump, you can get to both ends of the rack with the pump in situ.

If we're optimistically jumping forward to troubleshooting the hystat, my choice of gauges is the standard Cat bottom entry offering. Nice quality and a good price and availability. I don't favour the Cat hoses though. I find them a bit bulky. I prefer to couple the gauges with the Parker microbore style hoses.

You have to keep in mind that you are measuring pressure and not flow, so yes in most cases thin tubing is just fine as long as it is rated with a safety margin for the pressures you are testing for on the machine.I had to buy some of the test fittings they use on processor heads and the hyd. shop carries what you are talking about.

Picked up some of their hoses, can roll up a 6 footer and put in my shirts pocket.

Bob

Thanks for that info, Nige.They will water even more when you discover 6V-4157 is only the box with the gauges in it. There is another number (could be 6V-4158 but don’t quote me) that contains all the test hoses and couplings, adapters, pressure taps, etc, required to actually connect the test box to a machine. Last time I looked that group was about half the price of a test box. I think it’s called something like a “hose & fittings group”.

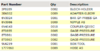

Yeah, sorry about that. Did a search for 6V4157 on the Internet which came up with 1U5796 on ch-part.com.FYI I don't see any differential pressure gauges in that list above.

8T0855 is 0-4,000kPa (580psi)

8T0861 is 0-60,000kPa (8700psi)

8T0863 is 0-250kPa (36psi)

The hydrostat troubleshooting can be largely carried out with one 580 psi gauge. There's a bit of tedious starting and stopping the engine and jiggery-pokery changing the gauge connector around involved, but it can be done. It's quicker and simpler with two or three gauges connected simultaneously but not worth the extra money if it's a one-off gig for you. The 8700 psi gauge is only needed if you get into the high pressure loop, but problems aren't as common here. The 36 psi one is for checking motor case drain pressure and you will probably only need it if the machine won't move at all.

Cmark said:As far as the FIP goes, if you haven't disturbed any of the adjusting screws or replaced any springs, just put it back together as it was and it should be good enough.

500psi might not be so odd - and probably cheaper. In general you are going to be measuring pressures probably up to maybe 400psi. You've got the specs in the manual, what do they say.?Assume 600 psi might be an odd range,

As per Data Recording Sheet on p.117 & 118:500psi might not be so odd - and probably cheaper. In general you are going to be measuring pressures probably up to maybe 400psi. You've got the specs in the manual, what do they say.?

If you go with aftermarket gauges just make sure they are glycerine-filled. It takes away the needle vibrations and makes pressures easier to read.