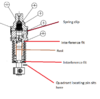

You need to get used to the idea of buying the special tools because you aint getting it fixed without them. The part numbers are 8T5287 and 8S2244. The retainer has internal splines which engage with the 8T5287. 8S2244 screws onto the bonnet and acts as a support. You also use it as the handle to remove the pump elements or rive the bonnets off. .....

Thanks very much. That picture of the Cat tool (8T-5287), alone, tells me so much - “picture worth a thousand words”. I know if you haven’t got the image handy on your computer it’s a rigmarole to post it in the forum. Thanks for your effort. And yes, I “aint getting it fixed without them”.

My service manual states 8S4163, but cross references to your P. N

o. If I had been more proactive I should have Googled that P N

o. and viewed a picture of the Cat tool.

Doubt whether the internal splines are rusted off the retaining bush. Climate out here isn’t as corrosive as for you poor buggers on the coast (assumption). Anyway, I now know what to do if they are gone.

In what way does tool 8S-2244 act as a support when screwed onto the bonnet ?

Yeah, I noted in the manual, the locating pin in the bore of the pump housing for locating the plunger gear teeth (and the dowel for locating the barrel). When I try to “rive” a bonnet out of the pump housing, what chance the barrel and plunger also comes out and breaks the locating pin ? AND without the pin, if the assembler was sure the gear keyed into the rack in the correct position, can the pump operate without the pin ?

New word “rive” … my education continues. I thought it was a typo, initially, then I looked it up.

Is there a kit that has all these pump special tools ?

Do you recommend a source for Cat spare parts ? My closest Cat dealer is Westrac in Dubbo. I’ve had a very helpful interaction with a young fella there, recently, regarding schematics for the hand pump to release the brakes, and many months ago regarding lubricants. Yep, this is my first Cat machine. More familiar with TD24s, very early TD9s, and more recently worked on a BTD8 (82 series).

Didn't have the heart to tell my father (now in his 90s) that I had painted his little dozer "Old Cat Yellow".

He has been an IH person all his life ... often broaching how the TD24s out performed and were more productive than the contemporary D8. Actually, I think they were D8H, 10 years younger. Bit heavier and more powerful, but they could NOT pull as well under load in a turn. I loved those 2 little leavers between my legs while Cat drivers had to pull steering clutch levers and stamp on brake pedals (from memory ?).

I’d like your (and Nige's) thoughts why I was able to start the engine 2 years ago, after sitting 10-15 years, but have these problems now ? The first time, it did go straight to high idle and the Governor control lever had no effect. Implies the rack may have been stuck, but was Ok when I re-started and weeks later.