Steves61

Member

I have a 2017 Cat 259D that will not lift the arms or move the bucket. It moves the track ok, the screen shows the right joystick functioning properly.

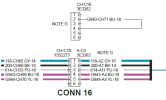

Is it possibly the door switch? It is a 3-wire plug. How can I jumper it to see if that is the problem?

Is it possibly the door switch? It is a 3-wire plug. How can I jumper it to see if that is the problem?