Interesting, thanks Nige. When I get the ECM installed I will follow-up with the results.Potentially. The 9th character (3) of the PIN immediately before the Serial Number (4) is referred to as a "check character" to make it harder to clone a PIN plate. Supposedly only the factory knows what it is for any specific machine.

View attachment 308238

-

Thank you for visiting HeavyEquipmentForums.com! Our objective is to provide industry professionals a place to gather to exchange questions, answers and ideas. We welcome you to register using the "Register" icon at the top of the page. We'd appreciate any help you can offer in spreading the word of our new site. The more members that join, the bigger resource for all to enjoy. Thank you!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CAT 226B Parking Brake Indicator and Armrest Indicator Are Flashing

- Thread starter AustinC

- Start date

I wanted to follow-up on this thread. My ECM got here a lot faster than I expected but I installed it and it doesn't work. My machine won't start and there are no lights on for the parking brake or arm rest. Any tips or suggestions would be wonderful. As of right now, I'm in the process of returning the item to the seller.Interesting, thanks Nige. When I get the ECM installed I will follow-up with the results.

Dead battery, Battery switch off. When it comes to electronics, I try not to mess around with aftermarket or rebuilt stuff. IMO their never as reliable as original. I believe this is were the phrase Pay to Play came from. Another reason the correct diagnoses is critical, or things add up in a hurry.

Battery is good, I put my old ECM back in and it started fine but continues to have the issue with the parking brake and armrest flashing. I wish I could afford to buy the ECM from Cat but I can't. I was hoping I was missing something after installing the new one but the install seems straight forward so I think the new/refurbished one from eBay is bad. I don't have to do any type of reset or anything like that when installing a new ECM, is that correct?Dead battery, Battery switch off. When it comes to electronics, I try not to mess around with aftermarket or rebuilt stuff. IMO their never as reliable as original. I believe this is were the phrase Pay to Play came from. Another reason the correct diagnoses is critical, or things add up in a hurry.

Nige

Senior Member

It is. The "software" in your Interlock ECM is hard-wired into a replaceable EPROM chip that plugs straight into the motherboard of the control.I don't have to do any type of reset or anything like that when installing a new ECM, is that correct?

If with your old ECM the engine would start but the problem was the flashing alarms allied to the park brake not releasing, but with the replacement ECM the engine won't even start then the replacement ECM is obviously bad - QED.

I figured the replacement was bad. Thanks for confirming.It is. The "software" in your Interlock ECM is hard-wired into a replaceable EPROM chip that plugs straight into the motherboard of the control.

If with your old ECM the engine would start but the problem was the flashing alarms allied to the park brake not releasing, but with the replacement ECM the engine won't even start then the replacement ECM is obviously bad - QED.

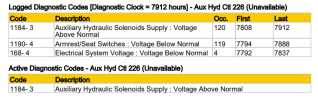

I want to keep up on this thread as I gather new information. I took my machine to CAT and they plugged into my Aux ECM with CAT ET.

Here are the results:

Long story short I picked up my machine and CAT didn't perform additional work on it.

Can anyone tell me if the Logged or Active Diagnostic Codes could be the culprit to my issue with the armrest and parking break indicator flashing? I know the interlock ECM is tied to the Armrest/Seat switch but I'm not familiar with these status reports (i.e. the differences between logged and active codes) so any additional info would be appreciated.

Here are the results:

Long story short I picked up my machine and CAT didn't perform additional work on it.

Can anyone tell me if the Logged or Active Diagnostic Codes could be the culprit to my issue with the armrest and parking break indicator flashing? I know the interlock ECM is tied to the Armrest/Seat switch but I'm not familiar with these status reports (i.e. the differences between logged and active codes) so any additional info would be appreciated.

Nige

Senior Member

Quite simple.I'm not familiar with these status reports (i.e. the differences between logged and active codes)

An Active Diagnostic Code means the Code is there right now - Active in other words.

A Logged Diagnostic Code means that the Code was Active at one time but is not Active at this point. Therefore it is Logged in the ECM memory.

Attached the troubleshooting procedure for 1184-3. Let us know how you get on.

Attachments

Will do, thank you.Quite simple.

An Active Diagnostic Code means the Code is there right now - Active in other words.

A Logged Diagnostic Code means that the Code was Active at one time but is not Active at this point. Therefore it is Logged in the ECM memory.

Attached the troubleshooting procedure for 1184-3. Let us know how you get on.

Quite simple.

An Active Diagnostic Code means the Code is there right now - Active in other words.

A Logged Diagnostic Code means that the Code was Active at one time but is not Active at this point. Therefore it is Logged in the ECM memory.

Attached the troubleshooting procedure for 1184-3. Let us know how you get on.

Hey Nige, after following these trouble shooting steps here are my results:

Step 1. - I'm getting .OL on all contacts.

Step 2. - I'm getting 0.00 volts.

According to the trouble shooting procedure my ECM has failed.

My question is surrounding both ECMS at this point. It seem that this test is testing the Aux ECM but at the beginning of this thread, I was originally trouble shooting the parking brake and seat belt indicator flashing relating to the Interlock ECM.

During the trouble shooting for the the parking brake and armrest indicator flashing / Interlock ECM, we discovered that there are inaccuracies in the trouble shooting (see post #55) so I want to make sure I'm not missing anything.

Should I trust the CAT ET and replace the Aux ECM or the previous trouble shooting and replace the Interlock ECM? OR maybe both have failed? This seems unlikely but I'm not sure at this point.

To summarize, I'm still dealing with the parking brake and armrest indicator flashing and the machine won't move. From my understanding and what we spent time trouble shooting, these are tied to the Interlock ECM.

Nige

Senior Member

I'm struggling to understand the test procedure TBH. Need to read up on it a bit more. I'll get back to you on that.

A question. Do you use the AUX Hydraulics on your machine for a clamshell bucket or other attachment requiring AUX hydraulics.? If not then I would suggest to focus your attention on the Interlock ECM for the moment.

A question. Do you use the AUX Hydraulics on your machine for a clamshell bucket or other attachment requiring AUX hydraulics.? If not then I would suggest to focus your attention on the Interlock ECM for the moment.

Chrisso

Senior Member

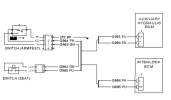

The 1184-3 code was active when the Product Status Report was downloaded from the ECM. It also shows that same code logged 100 times in the last 100 hours. In other words it's intermittent.Should I trust the CAT ET and replace the Aux ECM or the previous trouble shooting and replace the Interlock ECM? OR maybe both have failed?

If you're getting 0.00 volts between 42 & 3, and you can see that 1184-3 code active within ET simultaneously, only then would I suspect the ECM. You need ET connected to diagnose that properly.

Without ET connected it's hard to tell. The interlock system reports to both ECMs...Can anyone tell me if the Logged or Active Diagnostic Codes could be the culprit to my issue with the armrest and parking break indicator flashing?

Based on the above, certain pins need to be grounded and certain pins need to be open. The source is the 202 ground wire. Make sure that's good first. If the whole system is bypassed, and you still have your armrest light on, well that's most likely an ECM fault. Which one will be the next thing to determine. And ffs, if you bypass anything, make sure is goes back to how it was after testing. This is how people die.

Sorry for the delay, I've been out of town. The machine has the connection for the hydraulics but I've never used them. Here is a picture from the diagnostic from CAT. The wires have been like this since I've owned the machine and it was working so I didn't pay much attention to it.I'm struggling to understand the test procedure TBH. Need to read up on it a bit more. I'll get back to you on that.

A question. Do you use the AUX Hydraulics on your machine for a clamshell bucket or other attachment requiring AUX hydraulics.? If not then I would suggest to focus your attention on the Interlock ECM for the moment.

Maybe this is the reason for the 1184-3 code?

Nige

Senior Member

Do you have a better photo.? it's hard to see much detail.

TBH though I can't see problems in that connector causing an issue with the circuit for the AUX solenoid valves.

TBH though I can't see problems in that connector causing an issue with the circuit for the AUX solenoid valves.

Last edited:

Do you have a better photo.? it's hard to see much detail.

TBH though I can't see problems in that connector causing an issue with the circuit for the AUX solenoid valves.

I don't think it does either because the connection that is missing for these wires would leave them open like they are now

Here are some better pictures:

Nige

Senior Member

The damaged wires seem to have been insulated/isolated from one another pretty well. I can't see that throwing any spurious Codes.

The 1184-3 code was active when the Product Status Report was downloaded from the ECM. It also shows that same code logged 100 times in the last 100 hours. In other words it's intermittent.

If you're getting 0.00 volts between 42 & 3, and you can see that 1184-3 code active within ET simultaneously, only then would I suspect the ECM. You need ET connected to diagnose that properly.

Without ET connected it's hard to tell. The interlock system reports to both ECMs...

View attachment 311443

Based on the above, certain pins need to be grounded and certain pins need to be open. The source is the 202 ground wire. Make sure that's good first. If the whole system is bypassed, and you still have your armrest light on, well that's most likely an ECM fault. Which one will be the next thing to determine. And ffs, if you bypass anything, make sure is goes back to how it was after testing. This is how people die.

Thanks for the additional information. Do you have any input/trouble shooting steps on how I can go about testing the 202 ground wire?

Nige

Senior Member

The only thing I can suggest is under NO circumstances use the resistance function of your DMM. In the circumstances where the 202 wire could literally be “hanging on by a thread” it might well show acceptable continuity but will be incapable of passing any significant current. I would suggest to disconnect the wire at both ends (or at multi-pin harness connectors) then supply battery+ voltage at one end then connect the other end to machine frame ground via a 5A test light. If the wire will pass 5A without melting it’s in good shape.Do you have any input/trouble shooting steps on how I can go about testing the 202 ground wire?

Okay got it. I was able to borrow a power probe from a friend to supply + voltage.The only thing I can suggest is under NO circumstances use the resistance function of your DMM. In the circumstances where the 202 wire could literally be “hanging on by a thread” it might well show acceptable continuity but will be incapable of passing any significant current. I would suggest to disconnect the wire at both ends (or at multi-pin harness connectors) then supply battery+ voltage at one end then connect the other end to machine frame ground via a 5A test light. If the wire will pass 5A without melting it’s in good shape.

Sorry if this is an obvious answer to this question but I need to ask. I have a cheap 6v/12v test light, according to the owners manual the test light has a 12v/3w bulb and a 20amp clamp. Will this test light work or is the 5 amps going to blow the bulb? If needed I can go get a different test light.

Nige

Senior Member

No it will not. 5A at 12v is 60W which is a bit different to 3W. The whole idea is to get a decent current flowing in the wire so that if it is in any way dodgy it will pop.Sorry if this is an obvious answer to this question but I need to ask. I have a cheap 6v/12v test light, according to the owners manual the test light has a 12v/3w bulb and a 20amp clamp. Will this test light work or is the 5 amps going to blow the bulb? If needed I can go get a different test light.

TBH all you need is an automotive lamp holder with a 60W incandescent lamp in it and a couple of wires soldered to the lampholder. See first few seconds of this LINK. Disclaimer - I would solder the wires to the lamp holder rather than just twisting them like he did, but hey ho........