The transmission control valve harness, the short one with the internal splices that we were talking about above, is a 147-1771 for your machine S/N 1AL00505. That's the one that generally gives all the problems.

An easy way to get harness Part Numbers is this....

Look back at that snip I posted on the previous page. Above the 10-pin harness connector CONN 4 and slightly to the left is the letter "N", slightly to the right is the letter "F". These are the references for the two harnesses that meet at that connector. If you go to the ECM you'll find the harness plug at the other end of Line L46 from CONN 4 is also labelled "F".

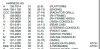

Go to Grid E-1, Page 2 of the electrical schematic and you'll find a Table with wiring harness letter identifiers and Part Numbers.

Harness "F" (RH Frame - XMSN) is listed as 143-3433.

Harness "N" (XMSN) is listed as 147-1771.

Asking a dealer for the numbers above might actually get you newer numbers but when that electrical schematic was drawn up those were the correct harness Part Numbers.